Designed for drilling holes with diameters up to 1mm, the latest range of micro-drills from St Helens-based Rainford Precision Machines Ltd (

www.rainfordprecision.com) is manufactured from a high-density micro-grain solid carbide that ensures a high level of rigidity.

This rigidity, combined with a special edge geometry, allows the ADL- and ADLL-series of drills to machine holes in soft ferrous and non-ferrous materials to depths of 25xD, 30xD, 33xD and 50xD. They have already been used on sliding-head turning centres for the precision machining of plastic components for the electronics and connector industries.

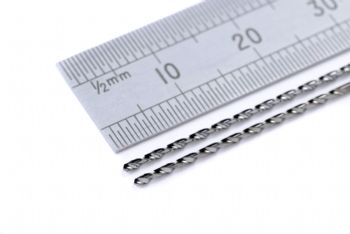

The drills, which feature a high-helix 30deg flute, are available in diameters from 0.3 to 1mm (in increments of 0.05mm) and with flute lengths from 10-50mm. The overall lengths are in the range 60-110mm.

Moreover, to ensure that these drills retain their edge sharpness and provide consistent drilling performance, they are uncoated.

Rainford says that not coating these drills actually enhances their life and drilling performance, as small tools with sharp edges are renowned for edge wear and chipping that is a consequence of applying a coating to a sharp edge.

Furthermore, coating small-diameter drills limits the sharpness of the cutting edge and ultimately the performance of the tool.