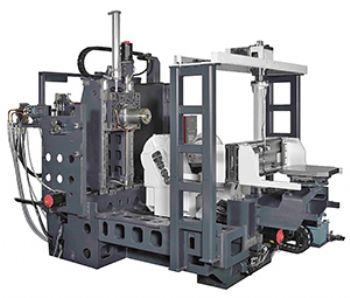

OKK’s HM-X6000 five-axis horizontal machining centre can accommodate workpieces up to 750mm in diameter and 700mm high. Moreover, parts are carried on an integrated 600mm pallet system for automatic loading to the trunnion unit.

Available in the UK from Hinckley-based 2D CNC Machinery Ltd (

www.2dcnc.co.uk), the machine has a trunnion unit with a 360deg B axis and an A axis that tilts between +20 and -110deg; the trunnion moves into and out of the machining zone on the 820mm Z axis for loading/unloading and undertaking machining cycles.

The 20-tonne machine features a column that moves right and left through the 1,050mm X axis. Y-axis travel is 900mm, while rapid traverse rates are up to 75m/min. Positioning accuracy in the X, Y and Z axes is ±0.002mm over the complete travel distance; the repeatability is ±0.001mm.

However, when the optional linear scales are specified, positioning accuracy is improved to ±0.001mm, with repeatability of ±0.0005mm. The circularity tolerance of the rotary table is within 0.005mm.

Moreover, the machine can undertake turning operations, making use of the 33rev/min speed of the B axis and the 10rev/min speed of the A axis. The 30kW BT50 spindle offers a speed range of 35-12,000rev/min and 600Nm of torque. Tool-to-tool exchange takes 2sec from the 40-tool magazine (there are options for up to 236 tool positions). Control is via a Fanuc 31i-A5 CNC.

To help boost rigidity, a dual-disc clamping system is used for the trunnion table; this gives a retaining force of over 10,000Nm for the A axis and 6,000Nm for the B axis. Double hydraulic and mechanical clamps are used to secure the pallet on the trunnion, which is held with a force of 2,900Nm.