Texas-based Tool Flo is a major manufacturer of high-quality carbide cutting tools, such as inserts for threading, turning, and milling. As tool life, geometry and stability largely depend on correct edge preparation, the

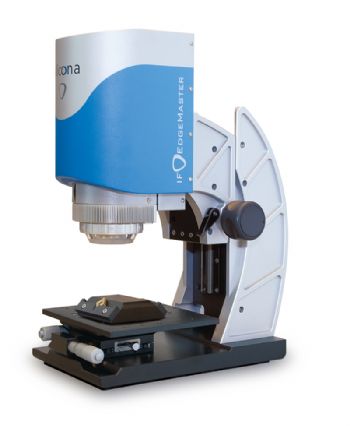

company uses an optical 3-D measurement system from Sevenoaks-based Alicona UK Ltd (

www.alicona.com) to help guarantee the quality of its inserts.

Tool Flo’s president, Dennis Flolo, says: “Alicona’s systems allow us to carry out high-resolution measurements of the geometry of cutting edges and the chipping and roughness of cutting surfaces in a fully automated process, free of possible user errors.”

Established in 1978, Tool Flo uses the latest in CNC grinding technology to ensure flawless edge preparation of inserts with edge radii of 2.5µm–0.1mm. At this level of precision, a measurement system capable of the highest resolutions is required to accurately inspect a tool’s edges.

Mr Flolo says: “Before we became aware of Alicona’s products, we used a profile projector to measure edge preparation, but it simply wasn’t precise enough to accurately identify edge radii in the micron range. It was only after switching to the EdgeMaster that we became capable of undertaking high-resolution measurement and the precise

mapping of edge shapes.”

The use of the EdgeMaster has made it possible for Tool Flo to map edges using two radius parameters, including a so-called ellipse fit. This is in contrast to conventional methods that use only one radius parameter. “When trying to measure the many undercuts and chamfered edges on inserts, our old measurement system quickly reached its limits. Now we can measure even complex geometries at resolutions previously unknown to us — and the results are traceable.”

As well as measuring radii, Tool Flo uses the EdgeMaster to verify edge parameters such as clearance, wedge, and rake angles. True and projected bevel lengths of the cutting edge are also measured.

“The EdgeMaster eliminates all sources of user error and therefore provides unambiguous and conclusive measurement results. The system offers repeatable and traceable high-resolution measurements, even when subjected to vibrations, extraneous light and fluctuations in temperature.

“Reference category and tolerances only need to be set up once; the EdgeMaster is then able to carry out measurements without requiring the adjustment of any further setting.

“The user simply places the insert into the respective grip and instigates the measurement routine; after a few seconds, a measurement log is produced. The measurement range is automatically selected by the system according to the pre-defined measurement area.”

In addition to the form and geometry measurement functions, as used by Tool Flo, a real roughness measurement of a tool’s cutting surface is extremely beneficial, as an insert’s ground cutting surfaces may display a range of defects such as micro-cracks, chips or burrs.

Such defects of the chipping and clearance surfaces are often where further tool damage originates and are detrimental to chip removal. Alicona’s systems allow users to precisely measure roughness across the entire cutting surface.