Birmingham-based Starrag UK Ltd (

www.starrag.com) says that its range of five-axis horizontal machining centres for aluminium workpieces has been expanded to include 150kW variants of the Scharmann Ecospeed and Ecospeed F models (which can accommodate components from 3 to 20m long), the Starrag STC 800X with 120kW spindle, and a three-machine Heckert HEC X5 range with 83kW spindles.

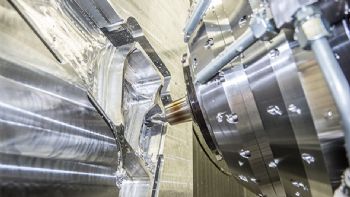

Starrag says the 150kW spindles on the Ecospeed machines can reduce machining times by 15-20% on typical aerospace structural parts, while the STC 800X can remove aluminium at rates of up to 10 litres/min.

With an A-axis range of -110deg to +60deg, the STC 800X is designed for complex machining in a single set-up, without the use of an angle head.

In addition, up to 465 tools can be held in the automatic tool-changer, while tombstone fixturing permits multi-part machining. The machine can accommodate pallets of 800 x 1,000mm and workloads of 2,000kg; it has a maximum workpiece swing diameter of 1,400mm and feed rates of 60m/min in the X, Y and Z axes.

The HEC 500 X5, HEC 630 X5 and HEC 800 X5 five-axis machining centres have work envelopes that extend from 1,000 x 800 x 1,000mm to 1,450 x 1,100 x 1,000mm and accommodate loads of 1,200kg. In all cases the 83kW main spindle motor produces speeds up to 15,000rev/min and torque up to 1,500Nm. The maximum rapid-traverse rate is 65m/min.

In tandem with the new 150kW spindles for the Ecospeed machines, Starrag has also announced the development of a chatter-monitoring function for the automatic recog-nition and analysis of unstable machining processes.

This continuously monitors spindle bearing temperatures, absolute vibration levels and tool imbalance; it can instigate a ‘spindle stop’ when pre-determined limits are exceeded.