ELC Laser Group, the first sheet metal sub-contractor in the Irish Republic to offer five-axis laser cutting, is using Radan’s specialist Radm-ax module as a springboard to becoming more design-focused (

www.radan.com).

In 1989, the Waterford-based company was the first one to introduce laser cutting into the Irish market, and operations manager David Power says that it continues to develop the latest technology, offering customers what he calls the “definitive choice in laser cutting solutions.”

ELC provides quality-assured design, cut and fabrication solutions for projects across a range of industries, including agriculture, aerospace, pharmaceutical, shop and hotel-fitting, automotive, materials handling and automation.

Having used Radan to program the company’s two flat-bed laser cutters — a Baykal BLS 4000 and a Prima Domino — for 13 years, Mr Power says that this software was the natural choice when looking to improve the way ELC controlled its five-axis Prima Rapido 2kW laser.

“The machine has a 3 x 1.5m bed and a 600mm Z axis, which gives us tremendous flexibility in cutting 10mm-thick mild steel and 6mm stainless steel.”

ELC brought five-axis laser technology to Ireland when a major customer’s project required this capability, and the company used another CAD/CAM system to drive it, but ELC’s requirements eventually outgrew the capabilities of this system.

Mr Power said: “We’ve had excellent success with Radan programming the flat-bed lasers. We’ve discovered that its Radm-ax specialist five-axis module is ideal for what we need — both now and in the future — to help us develop the company. We can cut and trim complex pressed and formed 3-D components — along with box and tubular sections — with total precision.”

3-D cutting

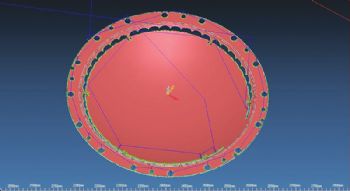

ELC’s five-axis laser system ensures total control of the cutting head, enabling chamfers to be cut on the edge of the material, or maintaining a 90deg angle relative to the cutting surface throughout profiling operations. The company makes full use of Radm-ax for BS&B Safety Systems’ work.

“We produce burst panels and explosion panels for them, primarily from stainless steel and nickel alloy. These are formed parts, so we’re cutting in 3-D, not 2-D; Radm-ax allows us to develop 3-D models and cut the parts extremely efficiently.”

Mr Power says ELC’s five-axis work has improved considerably since switching from its original software to Radm-ax. “It takes in SolidWorks or any other 3-D models and quickly creates the cut paths, allowing us to speed up the cutting process by at least 20%.”

With a long-standing reputation for being a successful cutting company, ELC is now looking to develop a more design-focused role and become a full design and fabrication ‘one-stop shop’.

“This will enable us to attract new customers, and Radm-ax means we can take in the 3-D model, lay it out on the computer simulation of the Prima bed, orientate it, apply tool-paths, then go round it setting the features we want.”

Prototyping is going to play a big role in the company’s plans, and Mr Power says all the Radan modules currently being used — the Radraft 2-D CAD system, Radan 3D, Radnest, Radprofile and Radm-ax — mean ELC will be able to add value in terms of how they create parts.

“Customers can come to us with a concept and we’ll design it from scratch, or they can provide a design and we’ll value-engineer it. Where the parts are formed, we take them directly onto the five-axis machine, and thanks to Radm-ax, we can now pre-fabricate some components and apply the cutting operation after we’ve fabricated them.”

ELC’s use of Radm-ax is growing all the time, as more customers ask them to produce components on the five-axis laser; the company is also looking to extend its services to the UK’s aerospace and automotive industries.

The software not only minimises programming time, the cut paths are more efficient, saving further time during cutting on the machine. Combining that with the comprehensive simulation and proofing tools streamlines ELC’s day-to-day production, while reducing costly errors and eradicating the need for dry runs.

The tool-paths are accurately simulated on screen, showing the angle of the nozzle as it moves around the part, providing instant feedback on whether or not a specific move is possible.

If any collisions are detected, they are highlighted both on the model and via on-screen messages. Mr Power says the software will play an important part in the next stage of ELC’s development.

“Our machines are also capable of laser-welding, and that’s something we’ll be exploring shortly. Radm-ax will program those operations, too.”