Sandvik Coromant, Halesowen (

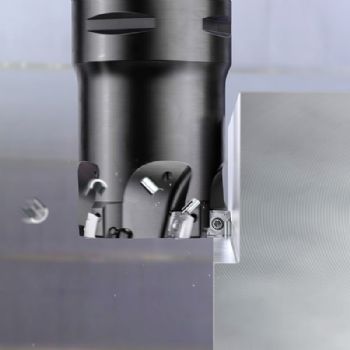

www.sandvik.coromant.com), has made its steel-milling grade GC1130 available for use with CoroMill QD and CoroMill 331 groove-milling cutters. GC1130, which is the latest Zertivo grade from Sandvik Coromant, is said to deliver high metal removal rates and secure performance levels in both wet and dry machining operations.

Already available for use with CoroMill 390, CoroMill 490 and CoroMill 495 shoulder- and chamfer-milling systems, this expansion of the application area makes the benefits of Zertivo technology, such as longer tool life and secure machining, available to a wider ‘user profile’.

Machine shops can now use grade GC1130 inserts with CoroMill QD for deep and narrow grooving in both external and internal roughing and finishing operations.

For additional groove-milling requirements, GC1130 inserts can also be applied to CoroMill 331, which is a multi-purpose side- and face-milling cutter. This tool can undertake grooving, shoulder milling, face milling, back-face milling, gang milling and circular ramping.

GC1130 has now been introduced to seven additional product families. Along with CoroMill QD and CoroMill 331, it is available for use with CoroMill 790 and T-Max long edge (shoulder milling), CoroMill Century (face milling), CoroMill 170 and CoroMill 176 (gear milling).

Project manager Björn Ericsson says: “Issues such as flaking, abrupt chipping and thermal cracks are commonly encountered when milling materials in the ISO P application area, especially when faced with unfavourable tool-paths, deep cavities or when using coolant.

“We have developed GC1130 to help machine shops overcome the consequential effects of reduced insert life and unstable production.”