The Design and Prototyping Group of the Advanced Manufacturing Research Centre (AMRC) (

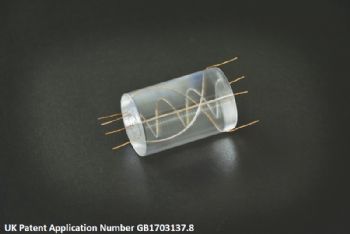

www.amrc.co.uk) with Boeing in Sheffield says it has developed a hybrid 3-D printing process that allows electrical, optical and structural elements to be introduced throughout an additively manufactured component during the build process.

The fully automated THREAD process is suited to a variety of additive-manufacturing (AM) platforms; it has so far been successfully demonstrated on machines used for 3-D printing polymer components.

AMRC development engineer and AM specialist Mark Cocking said: “THREAD has the scope to simultaneously add multiple industry-recognised threads of differing materials into one component, giving it additional functions. The development of this process is a potential game-changer.

“It could be used across many sectors such as medical, aerospace and automotive, where the weight and size of components are critical or where components would benefit from integrated data transfer and the protection of sealed connective tracks.”

Chris Iveson, who is driving the commercialisation of the technology, said: “We see THREAD transforming the functionality of additively manufactured components.

“Feedback from our contacts in various industries indicates a real need for this capability, with new potential applications being discussed daily. This is a great example of the AMRC using its unique expertise to solve real industry problems.”