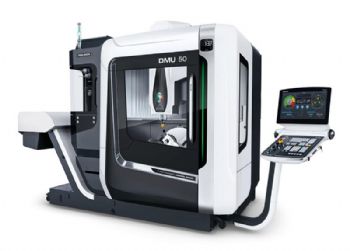

Now in its third generation, the DMU 50 machining centre from Coventry-based DMG Mori Seiki UK Ltd (

www.dmgmori.com) has been reintroduced with a larger capacity and upgraded specification.

With travels in the linear axes of 650 x 520 x 475mm, the machine now has a working volume that is 78% larger than that of its predecessor, extending the range of parts that can be produced.

Furthermore, the swivel of the rotary table, at -35 to +110deg, represents an increase of 28% over the previous model, allowing more-complex components to be machined.

Productivity has also been raised, as the rapid-traverse rate has been increased from 30m/min to 42m/min. There are 30 tool pockets in the standard magazine, although expansion up to 120 pockets is possible.

Moreover, customers can choose from either a 15,000 or 20,000rev/min spindle, while the table has an ergonomic loading height of 800mm and accepts workpieces weighing up to 300kg (a door width of 876mm provides good access to the work area, even when automation equipment for workpiece or pallet handling is in place). According to DMG Mori, accuracies of 6µm and better can be held on the DMU 50.

Contributing to this level of precision are a one-piece machine bed and integral cooling of the guideways, drives and table bearings. Linear scales and angle encoders provide feedback of axis positions.

A 21.5in ERGOline with CELOS and Siemens 840D, or a 19in ERGOline with Heidenhain TNC 640, can be specified as the control.