Hove-based CGTech Ltd (

www.cgtech.co.uk) is set to officially launch its latest ‘physics-based’ tool-path optimisation module, Vericut Force, at a series of UK roadshows.

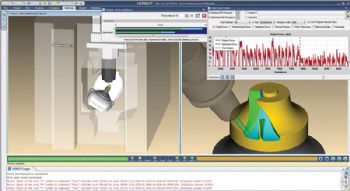

This module determines the maximum reliable feed rate for a given cutting condition, based on four factors: force on the cutter, spindle power, maximum chip thickness and maximum allowable feed rate.

It calculates optimised feed rates by analysing tool geometry and para-meters, material properties of the stock and cutting tool, and Vericut cut-by-cut contact conditions.

Through micro-analysis of the cutting conditions, Force also ensures that chip thicknesses do not exceed safe force or power limits.

Integrated into the latest version of Vericut (8.0.3), Force incorporates numerous enhancements, including features for better control of entry/exit speeds and ‘clean-up’ feed rates — plus tooling information has been re-arranged to be more intuitive.

Moreover, the module now receives input values directly from cloud-based tooling — and it benefits from new features that streamline ‘optimisation set-up’.

Other new features include improved chart displays that enable NC programmers to virtually ‘see’ and evaluate force, chip thickness and removal rates in NC programs before running on the CNC machine.

Force is said to be particularly beneficial when processing difficult-to-machine materials, especially when performing complex routines such as five-axis flank milling. According to CGTech, early users of the technology are already seeing productivity improvements of up to 50%.

Each Force roadshow will comprise a half-day seminar. They are taking place at Kyocera SGS Precision Tools, Wokingham (28 June), Nikken, Rotherham (4 July), and the Manufacturing Technology Centre (MTC), Coventry (6 July).