The 2017 R2 release of Edgecam (

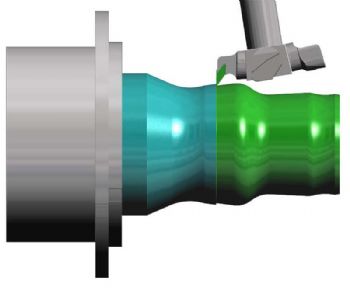

www.edgecam.com) from Cheltenham-based Vero Software introduces a turning cycle that includes B-axis movements.

This allows greater accessibility when machining complex profiles by dynamically positioning the insert.

Furthermore, the tool holder is gouge-protected during deployment, and the user gains additional control over the tool-path by using over-ride angles.

There are around 20 items of new and enhanced functionality in Edgecam 2017 R2, covering turning, milling, simulation and wire EDM. For example, when using the fixture database, it is now possible to measure fixtures and other work-holding devices.

This feature allows users to accurately measure the exact position and size of the fixture, as well as clarify its relationship to components, stock and any other work-holding elements.

Regarding feature finding, information transmitted by CadLink has been enhanced, with ‘limits and fit’ data now passed to Edgecam. This support covers CREO, SolidWorks and Autodesk Inventor CAD files.

The 2017 R2 release continues Edgecam’s evolution of updating cycle dialogs with pictures and ‘context-sensitive help’. In this instance, slot milling, project flow curves and project circular pattern cycles have all been updated.

Meanwhile, Edgecam’s machine simulator benefits from two additional enhancements. The ability to pick the target component while using view comparison was introduced in the previous release, and this has now been enhanced so that users can opt for ‘all components’ (this facility is said to be especially useful when working with numerous parts on a multi-loaded fixture).

Secondly, a quicker and more convenient way of rewinding the tool-paths has been introduced; when exiting the machine

simulator, rather than use the traditional menu option, users can now simply hold the ‘shift’ key.

Both the roughing and hole-drill cycles have been upgraded to be more consistent with existing features: when roughing to full depth, users no longer need to state a ‘cut increment’ value; in previous releases, it was necessary to provide a figure.

Furthermore, when set to ‘use current stock’, the 2017 R2 hole cycle no longer requires a Z-level value — the system automatically detects the start position of the tool-path.

For wire EDM users, numerous enhancements have been made to the machine configurator. Support for multiple versions of EDM Expert is now available, and a new technology setting has been added, allowing cycles to automatically switch to the appropriate EDM Expert technology page.