Hove-based CGTech Ltd (

www.cgtech.co.uk) has released the latest version of Vericut software, which offers machine simulation, verification and optimisation; it also simulates all types of CNC machining, additive and hybrid manufacturing processes — and can be integrated with leading CAM systems.

Managing director Tony Shrewsbury said: “Vericut 8.1 includes new modules and enhancements that simplify simulating a CNC machine. This release is all about various tools that can increase NC programmer efficiency, reduce production time, and detect costly errors before going to the shopfloor.”

Vericut Tool Manager imports 3-D cutting tools from Siemens Teamcenter Product Lifecycle Management (PLM) software, connecting directly to Teamcenter to reference files, thereby avoiding the need to create external uncontrolled copies of models on a local or network drive.

In one step, all 3-D cutting tools for a job are imported at once. The software now also enhances the support available for grinding and dressing operations; users can now simulate dressing where a secondary tool is applied to a grinding wheel to ‘freshen’ the grinding surface, or to change the grinding-wheel cutting shape.

Vericut simulates the dynamic compensation needed while the dresser is used, even while the grinder is engaged with the part.

Meanwhile, the software’s Force module is a physics-based NC program optimisation method that maximises chip thickness and creates more-constant cutting forces for significant savings in machining time.

Moreover, graphs and charts are displayed in real time, showing cutting conditions and forces as they are encountered by cutting tools. The data helps NC programmers identify undesirable cutting conditions.

Vericut’s new Section window makes it easier — and quicker — to see inside a part during simulation. This allows the user to check interference between the workpiece and machine components; it is also possible for the simulation to be continued while sectioned, and zoomed to achieve unobstructed viewing to pinpoint highlighted errors.

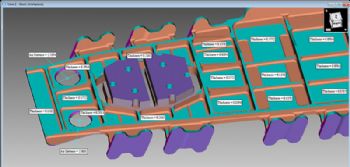

In version 8.1, the X-Caliper measuring tool (pictured) creates a measurement label on the part, with label placement customisable for optimal viewing.

Multiple dimensions can be displayed on the part to quickly document key measurements, create set-up diagrams or inspection aids; moreover, images with dimensions are easily referenced in Vericut reports.

Version 8.1 also includes a new Additive module, which simulates both additive and traditional CNC machining capabilities applied in any order.