Tewkesbury-based Quickgrind Ltd (

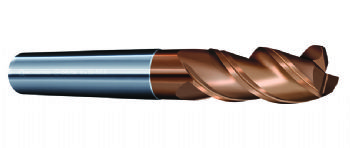

www.quickgrind.com) has released its Delta range of three-flute end mills — with extended reach, a ‘novel’ geometry and the company’s Xred coating.

These end mills offer a smooth cutting action courtesy of their variable-helix flute design and centre-cutting geometry, which is said to provide rapid evacuation of swarf and to minimise vibration.

According to Quickgrind, the combination of an h6 ground shank, a rigid micro-grain substrate and innovative geometry achieves high levels of surface finish, long tool life and high rates of material removal.

Primarily designed for machining stainless steels and high-temperature alloys, the durability of Delta end mills also enables machine shops to apply the tools to a variety of materials, including steels, cast iron, super-alloys and hardened steels.

From an application perspective, the centre-cutting geometry is said to make Delta suitable for HSC (high-speed cutting) milling applications, while the variable-flute geometry performs well in slotting operations.

The end mills are available in diameters of 3, 4, 5, 6, 8, 10, 12, 16 and 20mm.

Delta cutters are supplied with flute lengths from 10 to 38mm, and with extended neck lengths from 20 to 60mm, depending on the chosen diameter.

As well as square-end variants, the right-hand cutting Delta tools are available with a 0.25mm radii for 3 to 6mm-diameter tools, a 0.5mm radius for 8 to 16mm-diameter tools, and a 0.75mm radius on the 20mm-diameter tool.