With a heritage stretching back nearly 100 years, Frazer-Nash Manufacturing Ltd (

www.frazernash.com) is a precision engineering and manufacturing company, serving a domestic and international customer base that is predominantly involved in the food industry.

It focuses on providing solutions that cannot be met with standard products or those sourced from catalogues.

The Frazer-Nash name has a rich and varied history, from manufacturing cars in the 1920s and building powered turrets for use on bombers (such as the Lancaster) during World War II to producing innovative postal mechanisms and complex aerospace components in the 1960s. In 1990, the group was split up, and Frazer-Nash Manufacturing Ltd was formed.

Based in Petersfield, Hampshire, the company has a wide range of capabilities for low- to medium-volume production; these range from traditional milling and turning through to grinding and wire EDM.

A recent investment in a Renishaw additive manufacturing machine has further extended the company’s wide range

of competencies.

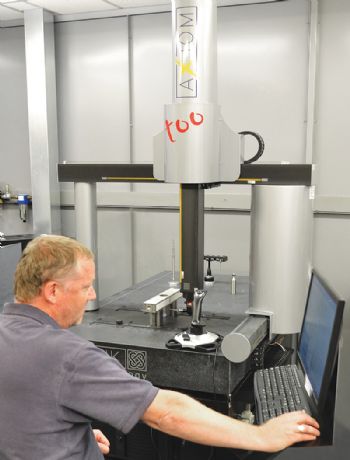

When increased levels of production recently began to place a strain on Frazer-Nash Manufacturing’s inspection department, a search was made for a CNC co-ordinate measuring machine (CMM).

After considering several alternatives, an Axiom Too was purchased from Gloucestershire-based Aberlink Ltd (

www.aberlink.com).

Frazer-Nash Manufacturing’s managing director, Paul Mortlock, said: “We pride ourselves on our quality. We are ISO 9001-certified and offer 100% inspection on manufactured items; we also provide certificates of conformance and full traceability on our work, where appropriate.

“Having evaluated several makes and models of CMM, we decided that the CNC version of Aberlink’s Axiom Too was ideal for our needs.

"As our production volumes are continuing to grow, the high precision of the Axiom Too, and its ability to rapidly inspect multiple parts in a fully automatic CNC mode, were major factors in our choice.

Furthermore, the machine’s ease of use meant that, after an initial short training course, our operators were able to master the CMM’s basic operations and perform a range of inspection routines.

“A follow-up training session then enabled our operators to master the CMM’s more-advanced features. Now, our quality staff can quickly measure one-off parts in a manual mode, or use a pre-written program to inspect larger batches of components in an automatic CNC mode.

“Also, when we produce repeat batches of smaller parts, we can quickly recall the relevant stored program, load a large batch of parts and start an automatic inspection routine.

"Moreover, the Aberlink Too’s ability to generate in-depth inspection reports and documentation will help us with our traceability records.”

Aberlink’s Axiom Too CMM is available in both manual and CNC variants, as well as a range of capacities. Furthermore, it can be used in either controlled environments such as inspection departments or in ‘less than perfect’ shopfloor conditions, thanks to its use of an aluminium bridge with a very low thermal mass; this material also minimises the machine’s inertia, resulting in a “class-leading” speed of operation.

The CMM’s table features a granite/aluminium honeycomb construction designed to provide natural damping, while further improving the machine’s thermal properties; and because the controller and all peripherals are housed within the Axiom Too’s workbench, the CMM has a relatively small footprint.

Meanwhile, Aberlink’s 3-D software creates a picture of the component on the computer screen, as it is being measured.

Aberlink says this means that “dimensions between the measured features, mirroring those that appear on the component drawing, can then be simply picked off as required.

“In essence, this software can automatically recognise and define the various features being measured.”