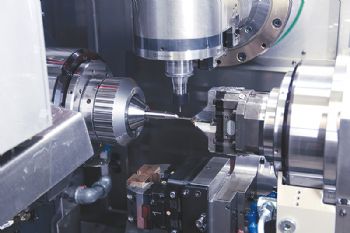

Dozens of engineers recently saw the capabilities of a Starrag Bumotec s191 linear CNC multi-function turn-mill centre, when it was shown undertaking the one-hit machining of small workpieces at the AMRC with Boeing

in Sheffield.

The machine, which was being demonstrated to visitors mainly from the aerospace sector, was seen performing grinding, gear cutting and broaching, as well as turning and milling routines. There was also a series of technical presentations.

Jonathan Knill, business development director at Victoria Production Engineering (part of the Hyde Group), said: “Not only were the presentations extremely interesting — especially the insight into using the Bumotec for machining aero-engine fuel injectors and other small precision aerospace parts requiring multi-discipline machining operations — the live demonstration clearly showed the machine’s flexibility and efficiency in multi-task machining in a single set-up. The whole event certainly provided much food for thought.”

Available from Birmingham-based Starrag UK Ltd (

www.starrag.com), the Swiss-built Starrag Bumotec s191 is accurate ±2.5µm within its work envelope of 410 x 200 x 400mm.

Also featured are linear drives and a high-level thermal stability. In addition, the machine’s main spindle (30,000 and 40,000rev/min speeds are available) is complemented by a sub-spindle that can turn in both the horizontal and vertical planes, for multi-process multi-tasking routines. Tool magazine options extend to 90 pockets, with a bar capacity of 32, 50 or 65mm. The rapid-traverse rate is 50m/min.

David Curtis, Technical Fellow at the AMRC with Boeing, said: “The Bumotec s191 gives us opportunities to develop revolutionary new machining processes in any material and for any sector.

"We are now looking for projects where we can take small, complex components and develop optimised cost-saving solutions that add value to UK industry.”