The latest generation of CNC systems from NUM (

www.num.com) is helping the US manufacturer Star Cutter Co to maintain its position as a leading manufacturer of machines for making cutting tools.

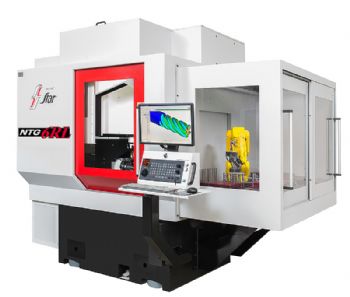

The company’s new five-axis tool and cutter grinding machine — the NTG 6RL — is based on NUM’s Flexium+ CNC platform and fully automates the high-speed production and reconditioning of complex cutting tools.

Founded in Detroit in 1927, Star Cutter now has six manufacturing facilities in Michigan and has been working with NUM for

almost 20 years. The machine manufacturer originally used another make of controllers for its machines, but the need to offer greater capability and make producing complex tool forms even easier resulted in it looking for a more-open CNC platform.

Bradley Lawton, Star Cutter’s chairman, says: “NUM was an obvious choice. The company is renowned for the open-architecture nature of its CNC solutions, and it has done much to remove the ‘black box’ mystique that is endemic to many competitors’ CNC products.

"Today, nearly all of our CNC machines use NUM’s CNC hardware and Numrotoplus software.”

Star Cutter’s NTG 6RL is a full linear five-axis tool and cutter grinder that can handle fluting, tertiary grinding, relief grinding and automated wheel change. As well as NUM’s Flexium+ CNC platform, it features NUMDrive X modules; these provide the drive flexibility that is needed to accommodate a variety of third-party linear and direct drive torque motors, as well as high-frequency grinding-spindle motors.

Furthermore, the Flexium+ platform can run grinding programs as large as 40MB directly from the NCK memory, while for very complex grinding cycles, the CNC system can execute cycles directly from its disk drive, via a high-speed data transfer protocol.