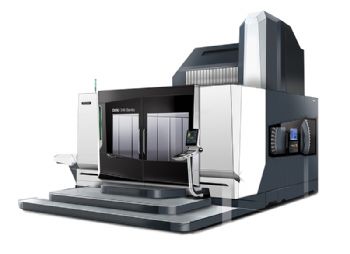

Said to be universally applicable across the aerospace, mechanical engineering and mould-and-die sectors, the DMU 340 gantry machining centre from Coventry-based DMG Mori (

www.dmgmori.com) has a one-piece thermo-symmetrical cast-iron (EN-GJS-600) bed and offers a work envelope of 3,400 x 2,800 x 1,250mm, which is expandable to 6,000mm in the X axis and 1,500mm in Z.

Linear drives in the X and Y axes offer upto 0.5g acceleration and (optionally) 90m/min rapid-traverse rates; there is also a ram featuring an integrated direct-drive C axis, as well as a B-axis milling head with direct drive and 50deg swivel to provide a fully interpolative five-axis machining capability for producing large and complex components.

According to DMG Mori, the machine achieves surface finishes down to Ra 0.3µm. The standard machine has a 4,400 ¥ 2,700mm table that accommodates workpieces weighing up to 10,000kg, although the maximum load can be trebled on request.

A range of HSK-A63 and HSK-A100 motor spindles is manufactured in-house; these offer speeds up to 30,000rev/min and powers up to 79kW (or 430Nm).

The SK40-SpeedMaster — rated at 15,000rev/min and 130Nm — is standard. There is space for 30 tools in the chain magazine, although an optional wheel magazine can accommodate 63 tools, extendable up to 183 pockets.

DMG Mori uses its Celos app-based control and operating interface with a Siemens or Heidenhain CNC system. The control has a 21.5in touch-screen display and 26 Celos apps to assist in scheduling work and optimising processes.

Furthermore, an Industry 4.0-ready interface, which is compatible with ERP systems and can be linked to CAD/CAM applications, integrates the machine into a customer’s production environment.