Cambridge-based NCG CAM Solutions Ltd (

www.ncgcam.com) has released the latest version (v16.0) of its NCG CAM software.

This release includes a number of new features, including: selected surface machining for waterline passes; combined passes for waterline and constant step-over; tangential extension for raster passes; five-axis flank machining; and many user-interface functions and enhancements.

Selected surface machining for waterline passes provides the ability to machine up to the surface edges without the need to create a boundary, the same as for shallow raster, radial and spiral strategies.

Staying with the waterline theme, a further new routine allows the creation of waterline passes between the upper angle of 90deg and a specified lower angle.

Constant step-over passes are then created to ‘fill in’ the shallow areas between the specified lower angle and 0deg.

Referred to as ‘linking’, this is a single operation from the top down, so that the linking order is a combination of waterline, constant step-over, waterline, and so on.

This strategy gives a smoother finish because it allows the machining to be done in one operation, avoiding the problem of cutter wear.

In previous software versions, extending raster passes would allow the cutter to ‘roll over the edge’.

Now, a new extension option creates passes that are extended at a tangent to the ends of the existing passes, and therefore extend the path beyond and away from the material being cut, thereby maintaining sharper edges.

A horizontal pass extension has also been added.

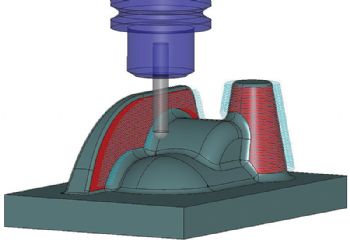

With regard to five-axis strategies, flank machining is a new process that can be used for turbo-engine components, including turbine and impeller blades.

The aim is to machine the part surface in only one cut, using the whole flute length of the cutting tool.

Another new feature that will soon follow in an NCG CAM v16 ‘point release’ will provide support for barrel-type cutters when using five-axis machining routines.

The defining feature of a barrel cutter is the circle-segment radius, which allows a much greater area of engagement between the cutter and the workpiece when compared with a typical ball-nose tool.

This larger engagement area allows the use of larger step-over values, while maintaining surface finish.

The basic style of the user interface has remained unchanged since NCG CAM software was first produced.

Modernising various aspects of the interface is in the process of being addressed and will be available in NCG CAM v16 point releases.

Improvements will include better handling and positioning of the tool-bars when the graphics window is narrow.