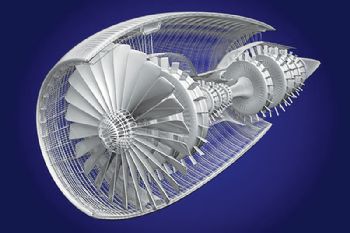

The production of China’s first turbofan jetliner engine has been achieved with the support of Berkshire-based Morgan Advanced Materials.

Its factory in China developed the ceramic cores needed to create air passages in the engine’s turbine blades.

The CJ-1000A engine is being developed for China’s first passenger jet — the COMAC C919, due to be rolled out in 2020. It will replace the imported engines that were used during the aircraft’s development.(

www.morganadvancedmaterials.com)

The new engine design uses hollow turbine blades and vanes to reduce the overall weight and provide internal cooling passages (to prevent the blades overheating when in use).

To achieve hollow blades with the required combination of light weight and robustness, ceramic cores are placed in the centre of the mould during casting of these components.

Morgan Advanced Materials was commissioned to create the ceramic cores at its manufacturing facility in Wuxi, Jiangsu.

The company worked with the engine manufacturers and designers to achieve the exact dimensions required for the internal cooling passages.

The cores are manufactured in heat-resistant materials that can withstand the casting process without compromising the integrity of each blade’s super-alloy construction.

After casting, the ceramic core is leached out to leave the blade hollow.

Morgan has supplied four core designs, and over 1,000 individual cores have been manufactured so far.

These number will rise significantly when the aircraft enters mass production, as 600 engines per annum will be required to meet the forecasted target of 150 aircraft a year.