Based in Savoie, France, Ketos manufactures foils and accessories for the gliding and sailing industries; it has achieved a 2.5-times faster turn-round by using the WorkNC CAM solution (

www.worknc.com) from Vero Software.

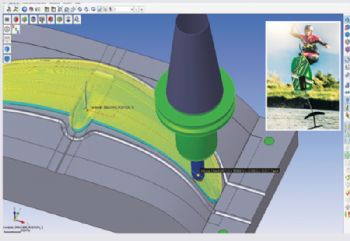

The company first uses WorkNC to machine prototype moulds and then produces just one or two parts. Managing director Anne Rostain says the accuracy with which WorkNC interprets its design data guarantees that the production mould is a perfect replica of the prototype.

“When we design our products, we aim to create precise high-performance profiles, so it’s essential that our machining operations reflect exactly what we’ve imagined and designed.

“We regularly test new profiles, so we program two or three new moulds each month for our high-tech composite components.”

Ketos was established over 25 years ago, and its customers are mainly surfing enthusiasts from all over the world, along with specialised retail outlets.

Machining is undertaken using a Raptor 2.5-axis CNC machine, driven by WorkNC three-axis software; design is undertaken with SolidWorks CAD.

Ms Rostain says: “With WorkNC, we maintain control over the complete cycle — from design through to in-house production — at a reasonable cost.”

Before the investment in WorkNC, the production process was completely manual; it relied on a model maker to produce resin moulds based on the prototype.

Ketos decided to invest in WorkNC as well as an NC machine tool to automate production and achieve much faster turn-round times.

“Each mould is unique and used to take a considerable time to produce. WorkNC allows us to be very responsive and to rapidly test new ideas.”