The Defence Science and Technology Laboratory (DSTL), which is based in Porton Down, has ‘revolutionised’ the production of titanium by reducing the 40-stage process to just two steps (potentially halving the cost).

Titanium is as strong as steel and half the weight — but around ten times the cost.

It is notoriously difficult and expensive to make which limits its wider use.

Titanium is widely used in military aircraft and submarines because of its high strength, light weight and corrosion-resistance see, but its high production costs make it difficult to justify in all but essential areas.

DSTL invested almost £30,000 in a research project at the University of Sheffield that led to the new ground-breaking manufacturing process.

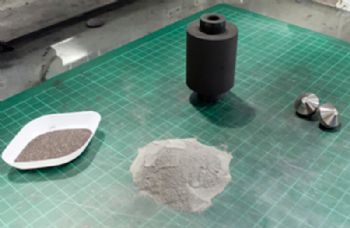

The pioneer of this revolutionary technique, Nick Weston, said: “FAST-forge enables near net shape components to be produced from powder or particulate in two simple processing steps, and the components have mechanical properties equivalent to a forged product.

"For titanium alloys, FAST-forge will provide a step change in the cost of components, allowing their use in automotive applications such as powertrain and suspension systems.”

So far, only small-scale trials have been carried out, but a new large-scale facility jointly funded by DSTL and Kennametal Manufacturing (UK) will enable larger components to be produced for testing.

Matthew Lunt, principal scientist at DSTL, said: “We’re really excited about this innovation, which could cut the production cost of titanium parts by up to 50%.”