The 2018 R2 release of Edgecam (

www.edgecam.com) from Cheltenham-based Vero Software contains 54 new or enhanced features that are said to improve productivity for manufacturers using a range of cutting technologies and machining strategies.

Subjected to most significant change, with 13 enhancements, is the completely transformed Tombstone Manager; its new ‘Add Tombstone’ function ensures that users never overwrite their master tombstone assembly file (referred to as the ‘seed file’).

Furthermore, the number of components that can be inserted in the Tombstone file is now limitless. Arguably the most significant individual enhancement, however, is the ability to retrospectively edit the CAM tool-paths; using the new edit and reload functions, Edgecam will independently open the inserted file, allowing the user to perform unlimited edits to the CAM instructions. Once finished, the seed file is automatically updated.

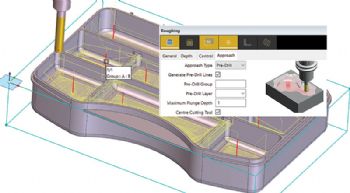

Among enhancements elsewhere in Edgecam, the way that the pre-drill-approach strategy is handled has been significantly improved within the roughing cycle. Rather than manually create drill hole positions, which is sometimes time-consuming, Edgecam 2018 R2 automatically creates the hole position and keeps the drilling tool-path associative to the roughing cycle.

Simply by activating the command, users can deploy the multi-level and depth functions within a hole cycle to automatically locate the best entry position for the drill cycle.

In a further development, the rough-turn cycle now includes several new lead parameters that permit the user to roll in and out of each cut with a tangential arc. Moreover, a bi-directional tool-path can be created, allowing the cycle to be used in conjunction with Sandvik Coromant’s recently introduced PrimeTurning inserts.

Improvements in the tool-path algorithm mean that Edgecam 2018 R2 provides a significant performance improvement with the ‘Pick Solid Faces’ function.

Time savings of over 50% are said to be achievable, thanks to the manner in which the cycle gathers data for tool-path calculations. Users will also gain further benefits when using the multi-pass function, as the strategy is now supported by a helical capability.

Found in both the milling and turning environments, the thread-mill cycle has been enhanced to allow closer tool-path control and greater flexibility. Five new parameters allow users to deploy peck and multi-pass tool-paths. This will especially help when machining hard materials or when a better surface finish is required.

A number of 3-D milling cycles in the mill-turn environment have become available when working in rotary mode. Previously, these cycles were restricted to planar mode.

Last but not least, the evolution of Edgecam’s inspection module continues with 14 enhancements, including full post-processor support from the code wizard. Major updates include the introduction of ‘NC Gateway’, which communicates with the machine tool, plus ‘Best Fit’ calculation, which allows workpiece alignment.