ModuleWorks — a leading supplier of CAD/CAM software modules for machining and simulation — and ZEISS (

www.zeiss.co.uk), which specialises in optics and optoelectronics, have combined conventional CAM features and the requirements of ultra-precision machining in a single CAD/CAM software solution that not only shortens the programming times for machining complex freeform surfaces but also improves the quality and cost-efficiency of producing ultra-precision optical parts.

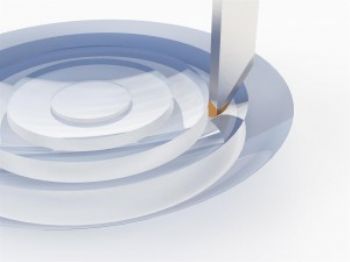

Ultra-precision machining is used for parts that need to be made to an accuracy of just a few µm and a roughness in the nm range.

Optical parts require ultra-precision machining for the optically effective areas of the part and conventional machining for the non-optical areas.

The Module Works/Zeiss software combines both types of machining in a single integrated solution (

www.moduleworks.com) .

The new software is powered by ModuleWorks’ 64-bit ultra-precision kernel, which is based on the company’s industry-proven five-axis technology for tool-path generation.

It has been specially developed to meet the growing demand for high-precision machining of increasingly complex geometries in the optics industry.

This kernel, which supports point clouds, NURBS surfaces and parametric geometries, uses multi-threading for fast tool-path generation, with “radial, spiral and parallel patterns for slow and fast tool kinematics”.

The freely configurable machine model supports all machine tool types for grinding and diamond turning applications, as well as grinding patterns for roughing, drilling, chamfering, slotting and contouring.

Full 3-D machine and material removal simulation software can also be applied, while the high-performance CNC ‘posting framework’ provides scriptable CNC data output (at a rate of 50,000 points per sec) and supports multi-threaded cloud posting.

The software is available as a library that can be integrated into existing CAD/CAM systems. A full demonstration version is currently available in the ModuleWorks Rhino CAM plug-in.