While there have been recent advances in 3-D printing of the incredibly light yet strong material graphene aerogel (the least dense solid known, at 160gm/m

3), achieving complex structures has been elusive and hampered

realising the material’s full potential.

To date, 3-D printing of graphene aerogel has been done using direct-ink or other extrusion-based methods, restricting the design of parts printed from this ultra-low-density material to simple geometries.

To overcome this limitation, for two years scientists and engineers at Lawrence Livermore National Laboratory (LLNL) (

www.llnl.gov) and Virginia Tech (both in the USA) have focused on 3-D printing this material using light — a method known as projection micro-stereolithography.

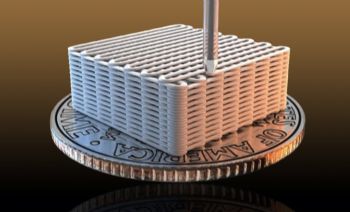

In a paper published on-line, the team reported a breakthrough, producing ‘micro architectured’ 3-D graphene aerogel structures with higher resolution and complexity than anything created before with other 3-D printing methods.

According to LLNL principal investigator Marcus Worsley, researchers began pursuing alternative printing methods while working to optimise electrodes for flow batteries; and to reach the level of intricacy required for the project, it was clear that the team needed a different approach.

In projection micro-stereolithography, ultra-violet light is used to project an image of a part layer into a photo-sensitive liquid resin, which is cured and hardened into the shape of the image.

Using this method, researchers were able to reduce the resolution in 3-D graphene aerogels printed through extrusion-based methods from around 100µm to about 10µm.