Starrag’s recent two-day 2018 Turbine Technology Days at its headquarters in Rorschach, Switzerland showcased a number of developments designed to improve the efficiency of machining turbine blades, blisks and engine casings.

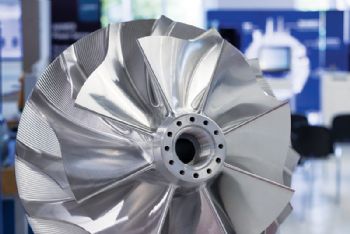

These developments included: a flexible manufacturing system (featuring 11 Starrag NB 151 machines) for automated blisk manufacture; a tool-changing angle head (a joint development with Benz) that allows a single head with HSK-B63 interface to replace the use of multiple angle heads; and the ‘adaptive roughing’ of turbine blades to eliminate ‘air cuts’, by using in-machine probing in conjunction with Starrag’s RCS programming routines.

Also previewed by Starrag, which has a UK subsidiary in Birmingham (

www.starrag.com), were a new larger-capacity NB 151 blisk machine (for components up to 600mm in diameter) and the ultra-high-accuracy Bumotec s191 mill-turn centre (this was demonstrated machining aero-engine fuel injectors).

The event, which attracted an audience of more than 160 aerospace manufacturing professionals from all corners of the globe, allowed Christian Walt (pictured) — Starrag’s recently appointed CEO — to ‘lay down a marker’ of what Starrag and its group product ranges have in store for the future.

He said: “Starrag’s broad product portfolio and inherent expertise give us a distinct advantage in terms of global operational excellence, and we will continue to build on that knowledge for the benefit of all our customers.

“The technology advances being demonstrated here reflect how we continue to respond to the needs of our customers and how Starrag is best-placed to satisfy those demands, now and in the future.”

Industrial partners

This year’s Turbine Technology Days was supported by tooling specialist Haimer, plus a number of other industrial partners.

Starrag’s managing director, Bernhard Bringmann, said: “We’re using a tool-kit of technologies to help customers gain ever-higher process stability.

“Adopting ‘built in’ technologies such as temperature control sensors and collision protection systems, as well as achieving minimal ‘air cuts’ through adaptive roughing and the elimination of alignment problems, we are enabling customers to optimise machining routines — often gaining improvements of up to 50% in production output.

““Moreover, components are becoming increasingly complex and require more-demanding machining.

Just a few years ago, it would have been impossible to machine certain parts in a single flow-line process, but having worked closely with customers, we have developed special-purpose fixturing and tooling and now provide a whole machining package.”

Mauro Fioretti and Andrea Maurizio — president and chief of technology respectively of family-owned Pietro Rosa TBM Srl — made a presentation entitled Strategic partnerships for innovation.

The Italy-based aerospace group, which has a division in North America, moved into the machining of forged blades in the 1980s.

Mr Fioretti said: “This was when our partnership with Starrag began. Today, we have six Starrag machines in our Italy plant and four in the USA at New England Airfoil Products.”

With annual revenues in 2017 of $70 million, Pietro Rosa TBM includes jet engine aerofoils (compressor aerofoils, along with variable, rotor, stator and turbine blades and discs), as well as steam turbines within its manufacturing portfolio.

Mr Fioretti said that customers’ ‘cost down’ initiatives had spurred continuous improvement in production regimes, which is where the use of Starrag machining technologies has come to the fore.

Mr Maurizio said: “We are selling flying hours, not just engines; and with engines operating at ever higher temperatures, there is an increasing need for compressor blades made of titanium and nickel-alloys.

“These super alloys are more difficult to machine, polish and test, which means we not only need the best five-axis milling machines but also smart fixturing, high-level process automation and process monitoring.

“Indeed, we need to automate as much as we can — and include as many multiple processes as possible into flow-lines.

“As aircraft programmes continue to grow — with relatively low batch sizes gradually being replaced by stable higher-volume quantities — it is clear that automation is the key to cost-competitiveness.”