Cutting-tool and tooling-system specialist Sandvik Coromant (

www.sandvik.coromant.com/uk) is to release two new grades — CB7125 and CB7135 — for interrupted hard-part turning operations.

These will complete the company’s offer for hard-part turning, complementing the existing CB7105 and CB7115 grades.

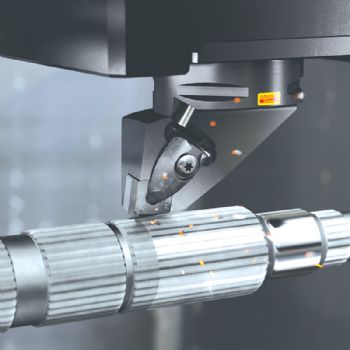

These latest grades are designed for medium-to-heavy interrupted cuts and for removing the hardened layer (depths of cut up to 2mm) in case- and induction-hardened steel components, typically for the automotive industry.

CB7125 and CB7135 are said to offer a longer and more consistent tool life, good levels of surface finish and consistent dimensional tolerances.

The new grades are optimised for turning steel materials with a hardness of 58-62HRC. CB7125, which is designed for medium intermittent cutting, features a new PVD coating that provides improved wear- and fracture-resistance for extended tool life; it has a medium CBN content and can be used for the turning of splined shafts and shafts with chamfered oil holes or pockets.

Further applications include the facing of gears, the hard-to-soft turning of crown wheels, and the removal of hardened layers.

CB7135 is targeted at the efficient longitudinal turning of gears and shafts with unchamfered keyways or pockets, as well as CV joint components (such as the inner/outer race and cage).

This grade has a high CBN content and offers a high level of fracture-resistance, as well as predictable machining results.

Available for T-Max P, CoroTurn 107 and CoroTurn TR tooling systems, the new grades come in both positive and negative basic shapes and various edge preparations.

Cutting-data recommendations for CB7125 include a cutting speed of 100-200m/min and a feed rate of 0.05-0.45mm/rev; for CB7135, a cutting speed of 80-160m/min and a feed rate of 0.05-0.4mm/rev should be achievable, depending on the application.