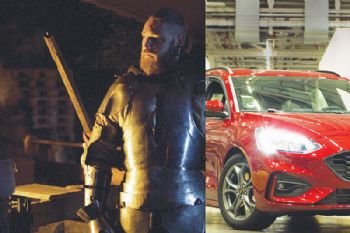

Hot-forming was once a technique that helped to protect knights in armour from the crashing blows of their rivals.

Now, Ford is applying a cutting-edge version of the same technology to help make its cars safer than ever before, using an automated hot-forming process (involving giant furnaces, robots and lasers) to shape and cut the parts that are integral to protecting the driver and passengers.

Dale Wishnousky, vice-president (manufacturing) at Ford of Europe (

www.corporate.ford.com), said: “We are building on techniques used to strengthen steel for thousands of years, incorporating modern materials and automation to speed and refine the hot-forming process.

The resulting boron steel safety cell helps to make the all-new Focus one of our safest vehicles ever.”

The hot-forming line was built as part of a recent 600 million euro investment in the company’s Saarlouis vehicle assembly plant in Germany.

The latest Focus makes extensive use of boron steel — the strongest steel used in the automotive industry — in its safety cell.

This helps to create a survival space in the event of an accident. In addition, the use of boron (found in skyscrapers) helps the new model to achieve a 40% improvement in the ability to withstand head-on crashes.

Hot-formed steel pieces are: subjected to temperatures of up to 930°C; unloaded by robots into a hydraulic press that has a closing force of 1,150 tonnes; and then shaped and cooled in just 3sec.

The boron steel is so strong by this point that a laser beam “hotter than molten lava” is used to precisely cut each piece into its final shape.