Based in Crewkerne (Somerset), VES Precision was established in 1991 to provide a range of precision engineering and sub-contract machining services to local companies — such as Westland Helicopters (now Leonardo Helicopters) and Normalair Garrett (now Honeywell Aerospace), both in nearby Yeovil.

Since then, VES has expanded considerably; it now operates from a modern 14,500ft

2 production facility and offers a range of services that include CNC milling and turning, EDM wire erosion, grinding, lapping and surface blasting.

Moreover, the company produces components from a broad range of materials, including plastics, stainless steels, high-speed steel, brass, copper, bronze, tungsten and aluminium — plus exotic materials such as Nimonic 90, Inconel, Stellite and MAR-M-247 (a nickel-based super-alloy).

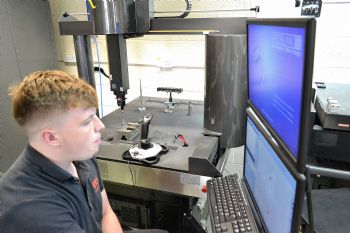

A recent significant increase in output placed a strain on VES’s inspection capabilities, prompting quality assurance manager Steve Trigg to investigate several precise and fast CNC co-ordinate measuring machines (CMMs); he subsequently bought an Axiom Too HS machine from Gloucestershire-based Aberlink Ltd (

www.aberlink.com).

He said: “Most engineering sub-contractors are geared up for either high-volume work or one-offs and small-batch work.

“Our success is largely based on our flexibility and offering ‘one-stop shop’ machining solutions; these range from one-off bespoke jobs through to large repeat-order production using a wide range of machining techniques and finishing processes.

Mr Trigg said: “Prompted by an ever-increasing work-load several months ago, we opened a new purpose-built machining facility that includes a five-axis machine with a pallet loader, three- and four-axis CNC mills and an overhead gantry crane.

“The additional capacity provided by our new milling hall has enabled us to considerably increase our output — hence our new Axiom Too HS CNC CMM.

“This has proved to be easy to use, and it was ‘up and running’ shortly after its installation.

“Moreover, the new machine’s speed and automated operation have resulted in considerably quicker throughput in our inspection department, which will be able to handle any foreseeable increases in production.”

The Axiom Too HS features an aluminium bridge with a very low thermal mass, allowing it to be used in either controlled environments or ‘less than perfect’ shopfloor conditions.

Moreover, the use of advanced materials that reduce the inertia of the CMM results in high-speed operation; while for increased accuracy, air bearings with optimised stiffness are used on all axes — plus a granite Y beam allows the pre-loading of bridge bearings in both directions.

Meanwhile — and using technology borrowed from the aerospace industry — the CMM’s component support comprises a granite/aluminium honeycomb construction that not only provides natural damping but also improves the machine’s thermal properties.

The Axiom Too HS also uses Aberlink’s intuitive 3-D software, which provides a simultaneous picture of the measured component on the computer screen; dimensions between the measured features that mirror those on the component drawing are then picked off as required.

In essence, this software offers an ‘intelligent’ measuring system that can automatically recognise and define the various features being measured; and its ease of use means that a complete novice can usually perform relatively involved measurement routines after just 5min of training.

In addition, customers enjoy the benefit of free Aberlink 3-D software updates for the life of their CMM.