Established in 1862 as a manufacturer of pen nibs, today Brandauer uses the strapline ‘From Pens to Particle Physics’ and has grown to be one of Europe’s largest contract presswork and stamping companies, making high-precision metal components — mainly electrical connectors for automotive, medical, environmental and telecoms applications — and supplying them to customers around the world.

The company operates with some 70 employees at a 45,000ft2 facility in Birmingham, and most of its products are stamped from a range of materials that include phosphor bronze, high-carbon steels, stainless steel, copper, brass and aluminium.

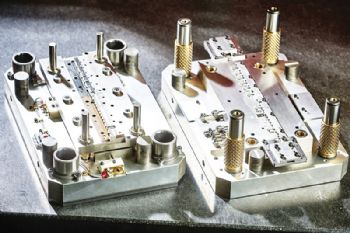

Most of the press tools are machined from D2 hardened tool steel and feature carbide inserts.

Manufacturing director Stuart Berry says that Brandauer needed integrated CAD/CAM software to fully support its CNC machine tools, which are capable of cutting to tolerances of ±1µm.

"It turned to VISI CAD/CAM software (

www.visicadcam.com) after finding that traditional parametric CAD systems led to a number of inherent issues, in particular those relating to file size.

Mr Berry said: “When we’re working on press tools with over 1,000 components, we design the parts to a micron, and even ‘size on size’. This means that a ‘fully detailed’ model quickly becomes a huge chunk of data, and the computer can take 30 or 40min to open it.

“Another issue with parametric systems is that when we made a change to one area of the design, it would affect other areas of the tool without us knowing, so we’d often end up with a design that we didn’t want.

"There are no data issues with the VISI Progress package, because it isn’t parametric as such. We can make design changes exactly as we wish without it affecting anything else in the tool; and because it is also a small file, there are no delays when opening it.

"Moreover, it is simple to design a full progression layout with VISI Progress’s built-in functionality, easily establishing where punches are to be sited and where the guidance pillars need to go.”

Design changes

Mr Berry highlights a number of design changes made during the 12-month development of a lead frame for power steering systems as an indicator of how important the non-parametric aspect of the software is.

“We were manufacturing a high-precision modular press tool to produce around 1.5 million components a year. Our design team used the original CAD data to create the tool in VISI Progress.

"The tool was constantly evolving, requiring a number of design changes, and certain parts had to be re-manufactured until we achieved the high precision accurate tool that our customer had ordered.”

All the individual parts were produced in Brandauer’s machine shop on Agie Charmilles wire-cut EDM machines using VISI Peps-Wire, with 2-D machining tool-paths for the company’s Mikron machining centres programmed using VISI’s CAM package.

Tool makers then built the tool to 1µm accuracy;it was then transferred to a Bruderer 51-tonne press capable of running at 1,200 strokes per min.

“We set the tool, carried out a full product review, and compared data from the first-off parts back to the CAD models. Everything was perfect, so we began manufacturing.”

Other examples of Brandauer’s automotive work include the EloPin, which is a push-fit solder-less contact used with electronic systems found ‘under the bonnet’; thanks to its low electrical resistance, it is particularly suitable for over-moulded hybrid parts.

Components made by Brandauer are also used in automatic dimming rear-view mirrors, airbag sensors and hydraulic braking systems, along with connectors for battery charging, satellite navigation systems and wiring-loom connector blocks. Medical products include surgical implants, as well as components for scanners and cardiac pacemakers; over the years, the company has produced more than 2.5 billion nose clips for protective and surgical face masks.

Three tooling ranges

Brandauer generally offers three tooling ranges, each with different lead times. Mr Berry said: “Our Precision range is our highest-specification and most accurate tool, with a lead time of between 16 and 22 weeks, depending on the complexity of the product.

Our Fixed Design tool can be produced within 10 to 15 weeks, while our Modular Tool usually takes between 18 and 25 weeks — again depending on how complex the end product is.

VISI is key to manufacturing all three ranges, and the software is a fundamental part of our day-to-day activities.

From design to manufacture, it ensures that we offer improved lead times while meeting all tolerances.”

As well as three seats of VISI Progress and two of VISI Peps-Wire, Brandauer has recently invested in Edgecam to handle its turning requirements; and the sales team uses WorkXplore, a powerful CAD viewer and analyser ‘from the same stable’ as the CAD/CAM software.

Mr Berry says WorkXplore was created to efficiently import and analyse all file types and sizes at high speed, adding that it plays an important role in the design and manufacturing life-cycle of the company’s stamping tools.

“When we receive CAD data from a customer asking us to price a job, the sales department looks at the file in WorkXplore, which allows them to provide an accurate quote.

“Once the order is confirmed, the designers start to analyse the product in VISI Progress and create a strip layout. We then construct the tool, using libraries which we have built up in the software; these comprise parts from all leading suppliers of progressive die tooling components, and they all comply with recognised global standards.”