The latest version of the HyperMill CAD/CAM suite — 2019.1 — is now available from Bicester-based Open Mind (

www.openmind-tech.com).

The software specialist has expanded the finishing module in the HyperMill MAXX Machining performance package and has included process optimisations as well as new functions for reducing calculation times.

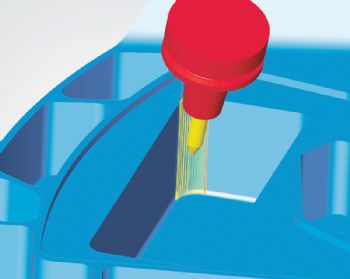

A new function is ‘Five-axis prismatic fillet finishing’, which supports high-feed milling. The processing takes place in a plunging and pulling movement with an extremely high feed, and this allows the highest machining performance possible with high-performance conical barrel cutters (also called circle segment or parabolic cutters).

Ball and radius cutters can also be used efficiently with this strategy.

Thread-milling options have been completely redesigned for HyperMill 2019.1 to improve convenience and user-friendliness for the programmer.

The module supports a variety of different thread-milling cutter types and allows easy selection of right-hand and left-hand threads or the definition of the millingdirection from bottom to top or vice versa.

The thread-milling feature also offers automatic approach and retract macros, a selection of roughing options and simplified programming.

HyperMill manages the order of the processing steps with job IDs. Changes to these job numbers have so far resulted in recalculations — these are now avoided to save time.

The improvement in job management now means that a job ID can be changed without having to subsequently recalculate the machining job in question.

The benefit of this new feature is transparent structuring and reduced calculation times, and the clamping position can be changed later without the machining jobs having to be recalculated.

Meanwhile, the tool database in HyperMill has been updated. Until now, there was only one comment field; in Version 2019.1 users now have the option of individually expanding the tool database.

As a result, information such as order numbers, prices or service life can be clearly stored, and the CAM programmer

can manage tools more easily.