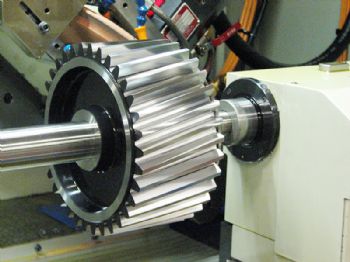

One of Europe’s leading producers of helical and spur tooth pinion gears has selected a GTG2 gear-grinding centre

from Rochdale-based Holroyd Precision Ltd (

www.holroyd.com) to test-grind a wide range of specialised gears and tooth forms.

Developed for the one-off or batch grinding of precision spur and helical gears, worms, screws and rotors of up to 350mm in diameter, GTG2 machining centres use “a unique machining system” to achieve accuracy to DIN 2 levels and better.

Holroyd regional sales director Steven Benn said: “The customer required a machine capable of grinding a variety of gears to the most exacting tolerances.

“The products to be manufactured included: spur and helical gears; gears with end-tip relief and root-fillet radius; worm-tooth forms such as ZA, ZI, ZK and ZN; worms with sunken tooth forms; dual-lead forms and both cylindrical and tapered roots.

“The GTG2 was selected for its versatility, reliability and uncompromising levels of accuracy. The latter is achieved through high levels of on-board machine intelligence and a machining process developed to compensate for ‘helical twist’ — a condition that occurs when helical gears are ‘lead crowned’ to improve meshing and reduce noise and wear.”