Over the past 40 years, Devon-based Rotamic Engineering Ltd (

www.rotamic.co.uk) has established a reputation for the manufacture of precision-machined components.

In addition to serving the demanding defence, Formula One and medical industries, the company has been a supplier to the aerospace industry for more than 20 years; it obtained the aerospace standard AS 9100 in 2006.

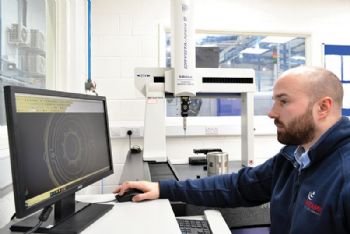

Operating from a large purpose-built manufacturing facility in Exeter, it has continually invested in advanced CNC machine tools and the latest metrology equipment, tooling and software, and it recently acquired a Crysta Apex S574 CNC co-ordinate measuring from Mitutoyo UK (

www.mitutoyo.co.uk).

Quality engineer Kai Kidson said: “Faced with the need to improve our CMM inspection capacity so that it could keep pace with increased levels of production, we considered several CMM options — and also took advice from our customers.

In addition to Mitutoyo CMMs being recommended by most of them, each spoke highly of the levels of service provided by the company.

An excellent practical demonstration at Mitutoyo’s Andover HQ then persuaded us that the S574 CNC CMM was ideal for our use.

“When compared to the other CMMs we looked at, we considered that the accuracy and repeatability of the Mitutoyo CNC CMM would give us the capability to inspect components with challenging dimensional specifications.

“Installed in our environmentally controlled inspection department, it is proving easy to use and can inspect complex high-precision parts with speed and efficiency.

“In addition to inspecting single parts, we can now place a large batch of components on to the CMM’s granite bed, recall an existing program and perform a highly efficient mass inspection routine in automatic CNC mode.”