The University of Strathclyde’s Advanced Forming Research Centre (AFRC) has set its sights on the space industry, working with Airbus Defence and Space (Airbus D&S) and TWI Ltd to bring the manufacture of space propellant tanks back to the UK.

In a two-year collaboration funded by the European Space Agency (ESA), the AFRC is using its expertise in forming and forging to advise Airbus D&S on advanced manufacturing methods for the tanks.

It will look at making the design more efficient and economical by producing the initial component at as near to net-shape as possible, substantially reducing the machining time (and the waste of costly metals such as titanium).

Renato Bellarosa, research and technology manager at Airbus DS, said: “Propellant tanks are key strategic items that we currently procure from Germany or the USA; we are working to re-establish the capability to make them in the UK, which was lost when the parent company of the firm involved took production to Germany.

"The collaboration with the AFRC fits into a general road-map that aims to develop this capability. There is also export potential in this programme.

"We have customers overseas — big players in satellite manufacture — who we believe would be interested in this new manufacturing approach.”

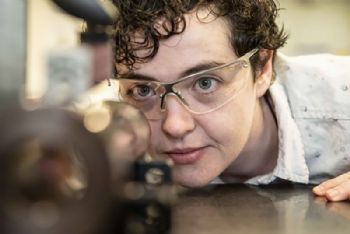

Jill Miscandlon, who is leading the project at the AFRC (

www.strath.ac.uk), said: “A tank is generally made of two hemispherical domes and a cylindrical section. The parts are forged, heat-treated and machined down to the required final thickness before being welded together.

"They are very thin, and machining them down from the original thickness results in significant material waste — in addition to the high cost of the machining.

“Over the past four months, we have been looking at methods of achieving near net-shape manufacture while maintaining the material properties, because each tank has to be structurally sound.

"It must be strong enough to store propellant under high pressure during a mission’s lifetime, which could be more than 25 years, but it should vapourise on meeting the upper atmosphere, so as not to present a risk to people and facilities on Earth.”