Renishaw (

www.renishaw.com) will be showcasing its smart technologies and intelligent process control solutions on three stands at

EMO.

These include high-speed multi-sensor measurement systems for CMMs; high-accuracy and high-speed products for machine tool probing; flexible shopfloor gauging systems; new calibration and encoder innovations for machine builders; and new additive-manufacturing solutions.

Visitors will be able to discover the company’s diverse portfolio of technologies for smart manufacturing and witness the benefits of Industry 4.0 in action, including process automation and innovations in collecting and managing actionable data about devices, processes and parts.

Renishaw’s director of industrial metrology applications, Paul Maxted, said: “Although ‘smart manufacturing’ is now being widely discussed, Renishaw has been developing and implementing smart factory principles successfully for over 25 years in our own manufacturing operations.

Trade fairs like

EMO 2019 represent an ideal forum for us to share our experiences and insights with international visitors from a variety of industries, and to reinforce our role as a partner for innovative manufacturing.”

The Metrology and Quality Assurance zone will be home to Renishaw’s largest stand (Hall 6, Stand D48).

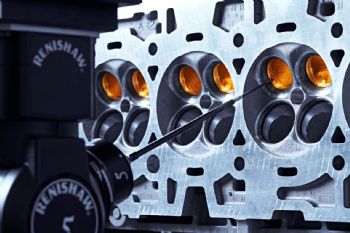

Here, visitors will be able to see the company’s award-winning REVO five-axis measurement system in action and discover how it delivers high-performance multi-dimensional inspection, including surface finish analysis.

To showcase the REVO system’s latest blade measurement capabilities, there will be a demonstration of an aerospace component being inspected on a co-ordinate measuring machine (CMM).

Also on display will be Renishaw’s modular and custom metrology fixturing, as well as a demonstration of its first automated direct loader transfer system for use with CMMs, which complements the benefits of automation and rapid throughput that the REVO system brings.

Renishaw’s Equator shopfloor gauging systems are being used to great effect around the world to measure a vast array of manufactured parts, particularly in the aerospace and automotive industries.

They enable the intelligent control of manufacturing cells and lines by delivering highly repeatable, thermally insensitive, versatile and reprogrammable shopfloor gauging.

Renishaw will also introduce its first-ever Solutions Bar. Visitors will be able to ask about a variety of process control, metrology products or manufacturing queries, while enjoying refreshments.

Within the Precision Tools zone (Hall 3, Stand E36), Renishaw will focus on smart manufacturing technologies for the metal-cutting sector.

Using its machining demonstration cell with automated part loading, on-machine probing and off-machine gauging, the company will demonstrate how automation, measurement and feedback can deliver process control throughout all manufacturing stages.

The cell demonstrates how complementary technologies can contribute — throughout the manufacturing process of a CNC-machined part — to achieving high levels of productivity and manufacturing capability.

Visitors will also discover Renishaw’s full range of on-machine and smartphone apps, which make installing, configuring, using and maintaining probing systems even easier, saving time and maximising shopfloor efficiency through enhanced automation.

Providing information in a simple convenient format, Renishaw’s smartphone apps are available globally in many languages and can be seamlessly integrated with a wide range of CNC systems.

In addition, an enhanced version of Renishaw’s Reporter on-machine probing app, complete with MTConnect data streaming capability, will be showcased.

Furthermore, Renishaw’s IPC software will showcase connectivity between the demonstration cell’s Equator gauging system and the machine tool’s controller, providing automated updates to machine parameters and offsets.

Extending Renishaw’s smart manufacturing technologies further up the process chain, its stand in the Additive Manufacturing zone (Hall 9, Stand I23) will showcase its latest additive-manufacturing (AM) systems and solutions.

This will include a live demonstration of the RenAM 500Q — its ultra-high productivity multi-laser system — building metal components.

InfiniAM Central (its remote process monitoring software for AM systems) will provide ready access to machine data. This Industry 4.0-ready connected system enables the remote monitoring of AM build processes on computers and mobile devices, including near real-time insights into live AM builds and access to historic build analysis.

System sensor and build information is displayed in graphic form to enable intuitive in-depth analysis.