Derby-based co-ordinate measuring machine (CMM) manufacturer LK Metrology Ltd (

www.LKmetrology.com) has introduced a Web-based platform that is aimed at multi-national organisations with factories world-wide, but is equally applicable to medium-size companies with several production facilities in one country.

Designed to help production departments monitor and control inspection activities ‘round the clock’ and consistent with the aims of Industry 4.0, the new Metrology Gate portal provides remote access to information on the status and performance of all connected metrology devices.

The information available includes measurement results and a summary of errors, a record of program changes, up-time of the CMMs and overall equipment effectiveness.

Historical logs assist troubleshooting and warn when routine maintenance is due — not only of the inspection machines but also of the machine tools or other equipment on which the components are being made.

Furthermore, comprehensive daily reports include total output per shift and the number of parts measured, sudden changes in process averages, and comparisons between the different machines producing the components.

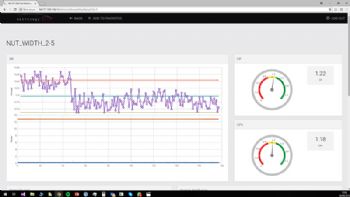

Graphical CAD reports, statistical process control (SPC) analyses with Cp and Cpk results, and environmental logs (including operating temperature) are generated and communicated, alongside charts to aid interpretation and understanding.

In the case of critical dimensional discrepancies or hardware failure, the software shares the information with users immediately by sending alerts via e-mail, SMS, WeChat or WhatsApp. Normally, the data

acquired is stored in the cloud, but it can be held on servers in different countries if preferred, or even on an individual computer.

However, one of the major benefits of Metrology Gate is that it is not necessary to travel at all to gain access to the information, cutting costs and saving an enormous amount of time — and the quality control data is acquired automatically, avoiding the risk of human error.

Moreover, a hierarchical permissions structure can be built into the platform, so that personnel have access only to information relevant to their needs.