With a name derived from the Japanese term for craftsman or artisan, Takumi Precision Engineering has been established in Limerick for over 20 years.

The company has invested heavily in recent years; a recent factory expansion has taken floor space to 50,000ft2, and

over 5 million euros have been invested in new machine tools and CAM software.

Takumi Precision (

www.takumiprecision.com) works for the medical-device, pharmaceutical, aerospace and precision-engineering sectors in Ireland.

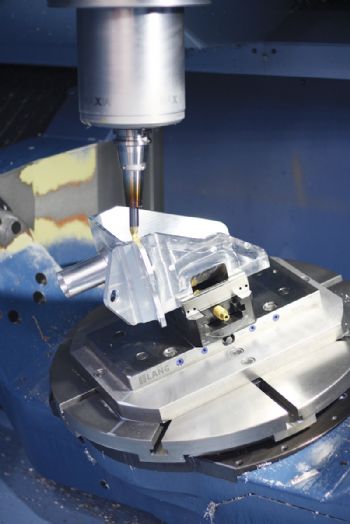

Among the parts manufactured are orthopaedic implants and instruments, cardiovascular assembly aids, medical-grade rasps, balloon moulds and delivery system components, as well as aluminium wing, brackets and fuselage components for the aero industry and electrical, electronic, mechanical and optical engineering components.

Over the years, Takumi Precision has invested in turning centres from Tornos, Doosan and Miyano, along with three- and five-axis machining centres from Doosan, Spinner and — most recently — Matsuura.

One of the company’s core investments has been HyperMill CAM software from Bicester-based Open Mind Technologies (

www.openmind-tech.com); this purchase was driven by the introduction of ‘barrel tool’ technology, an influx of five-axis machines and the limitations of previous CAM systems.

Commenting on changes at Takumi Precision, managing director Gerry Reynolds said: “Only five years ago, 90% of our work was for the medical industry, with the remainder taken by a number of sectors — including aerospace.

"We had an opportunity to increase our production for the aerospace market, increasing volumes from batches of one to three parts to continuous batches of 10-15 for the Airbus A220, previously known as the Bombardier C-Series.

"We had to invest in five-axis technology to accommodate the ramp-up of complex aerospace work and we have bought 13 five-axis machines in the last five years to support this.”

The investment has paid dividends, with aerospace work increasing from 5% of turnover to almost 60% in less than five years.

However, this is not to the detriment of the medical business, as Mr Reynolds confirms: “Our business has doubled in size in the last three years due to the increased aerospace work, but the medical sector remains crucially important to our business, comprising 40% of it.

"The volume of work has not reduced, it just hasn’t grown at the level of aerospace work. We now have 87 staff and are targeting a monthly turnover of 1 million euros.”

Introducing CAM

Speaking about Takumi Precision’s association with CAM, Mr Reynolds said: “Ten years ago, I didn’t understand CAM and would have argued against it.

"However, there was a necessity for CAM to run our machines; at the time I called it ‘finger CAM’, as we were programming at the machine.

"We progressed to a more comprehensive CAM system and eventually installed eight seats of software.

However, a visit to the AMRC introduced us to Ceratizit’s barrel tools and Open Mind’s HyperMill CAM system; these proved to be a ‘game changer’ for Takumi Precision.”

Having already made significant investments in CAM software, Mr Reynolds was apprehensive at the prospect of changing systems.

“We had spent a lot on CAM packages over the previous five to six years, and what we had worked relatively well, although there were a few issues with processing speed, occasional crashes and some feature limitations.

"It was the barrel tool machining features within the HyperMill MAXX Machining high-performance strategy that appealed to me, but I wanted my team to take the lead, as they would be the ones using the software.

“They attended HyperMill demos, and when they asked our existing CAM vendor — and others — if the barrel tool feature and the mirroring package were available, they were told ‘it’s on its way’ or ‘it’s in development’.

“We quickly moved to HyperMill, buying our first seat 18 months ago.

"We now have six seats of HyperMill and are phasing out our previous CAM system.”

The primary reason for Takumi Precision investing in HyperMill was the potential of barrel tools to significantly improve productivity.

Mr Reynolds said: “This software and the use of barrel tools with their innovative geometry allow us to step-down 5-10mm as opposed to 0.4-0.8mm when finishing pockets, walls or profiling features.

“This instantly reduced finishing cycles by at least 70%, giving us a minimum overall cycle time improvement of 30% on every component.

“However, the benefit is not just the cycle time improvement.

“We have historically had a number of staff undertaking finish-polishing of parts to ensure that our surface finishes exceed customer expectations.

"Despite the increased speed and step-down/step-over rate with HyperMill MAXX Machining, the surface finishes are much better than before.

"This is because the barrel tool has a higher engagement rate that keeps the tool in constant contact with the workpiece.”

Another feature that persuaded Takumi Precision to invest in Open Mind software was the mirroring feature. “In the aerospace industry, almost everything is manufactured with a left- and right-hand component.

"The mirroring feature in HyperMill is remarkably comprehensive; with just a touch of a button, we are reducing our programming times on most components by 50%.

“We have eight programming staff, and the mirroring feature is effectively doubling the productivity of this team.

“HyperMill is also much faster than our previous CAM systems, eliminating unforeseen PC crashes and massively improving the reliability, processing and delivery of our data to the shopfloor.

"The software also includes HyperCAD, which has eliminated our reliance on CAD packages like Inventor. We can now expedite jobs seamlessly through HyperCAD to HyperMILL — further making life easier for our programming team.”