Oxfordshire-based Prodrive (

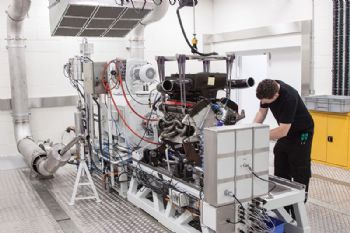

www.prodrive.com) has opened its new advanced Powertrain Development Centre (PDC) in Banbury, to develop solutions for the automotive and motor-sport industries.

The purpose-built facility represents a £5 million investment and was constructed over a period of six months.

It reinforces Prodrive’s ability to develop the next generation of electric, hybrid and internal-combustion engines for road and competition applications, while also strengthening the services that it offers to its motor-sport and

technology clients.

Chief powertrain engineer Arthur Shaw said: “The PDC marks a massive step forward in terms of our engine development capability and complements our existing skills in the design and development of all types of powertrain.

"The high specification of our new dyno means we are in the best position to calibrate units, allowing our customers to enjoy potential savings in terms of cost and time in comparison to physical testing on the road or track.

"Additionally, with the new facility bringing the differing stages of our powertrain development all under one roof — spanning the build of the engine right through to its installation in a chassis — there are further efficiency benefits that can be passed on to customers.

“This is one of the biggest investments that Prodrive has ever made, but with our motor-sport operations continuing to grow at a pace and increasing enquiries for the development of complex electric vehicle and hybrid technology, now is the optimum time for us to introduce our PDC.

"The significant expenditure underlines how committed we are to developing future powertrains and enhancing our service, enabling us to offer clients one of the most advanced facilities of its kind in the UK.”

Core to the new PDC is a 660kW transient dyno, one of the most powerful of its kind in the UK, which with temperature, humidity and pressure-controlled induction air can replicate all running conditions, while also providing cooling for engines and electric-vehicle batteries and motors.

The ability to simulate exact running conditions means the dyno is particularly suited to durability and performance testing, as well as emission simulation and development.

Complementing the transient dyno cell is a dedicated engine build room that can accommodate the assembly of up to 12 units.

This capability, coupled with the PDC being adjacent to the main workshop, enhances Prodrive’s ability to build complete vehicles and cater for niche OEM projects requiring around 200-300 units in short time-frames.