Oxford-based

Alloyed (formerly OxMet Technologies) has invested in a £300,000 electro-thermal mechanical testing (ETMT) machine which now resides in the company’s 1,000m

2 laboratory where it carries out metal research, testing and characterisation.

Alloyed brings together the advanced technology brands Alloys-By-Design (ABD), Betatype, and Alloyed Digital Manufacture (ADM) and specialises in optimising advanced digital metal manufacturing applications and the new machine will make it one of a small number of private companies globally to have the technology ih-house.

Gael Guetard, Alloyed’s Rapid Alloy Research Centre director, said: “While the ETMT machine adds hugely to our in-house technology portfolio used on behalf of an array of customers working on exacting AM and non-AM metal product applications, it is the combination of the technology with the experience of the Alloyed team that is the real strength.

“The company’s unrivalled expertise lies in using advanced metallurgy, the latest simulation techniques, and a deep understanding of the factors that drive alloy performance.

“Alloyed focuses on multi-scale materials and multi-physics modelling, prediction and analysis of fatigue and failure (an area enhanced by the ETMT machine), and the optimisation of complex manufacturing processes, including AM.

“While many customers have come to us since we installed the ETMT machine to take advantage of its superior attributes, it is often a gateway for them to then take advantage of the wide variety of services that Alloyed can offer for advanced metal manufacturing projects.”

Installed just over one month ago, the ETMT machine now makes Alloyed a ‘one stop shop’ for a number of metal tests that would have previously only been possible through the agency of a number of different testing companies using a wide range of technologies.

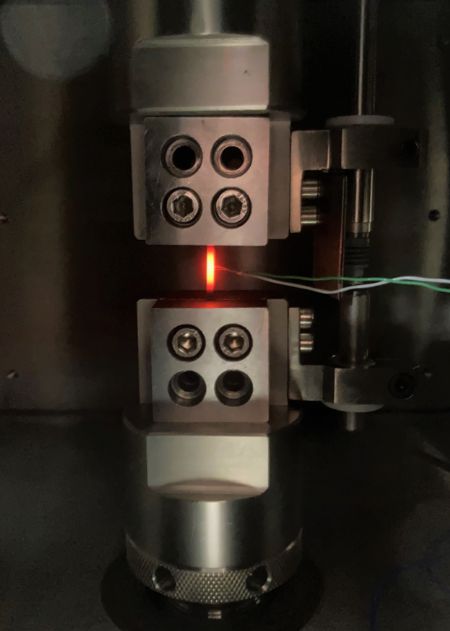

The ETMT machine can perform tensile and compression tests, creep tests (also called stress-rupture tests), and fatigue tests. Tests can be undertaken in air, vacuum, or foreign gases such as Argon.

The temperature of the sample being tested is controlled by the Joule effect, meaning that temperatures in excess of 1,000°C can be attained. The ETMT machine can also quickly heat and cool samples, affording the ability to cycle the temperature or perform in-situ heat treatments.

Mr Guetard added: “At Alloyed, we have equipped the ETMT with a ‘state of the art’ digital image correlation (DIC) system, which allows us to optically measure strain on the sample during testing. The machine is well suited for miniature test specimens, which allows us to obtain site-specific mechanical properties from large parts such as forgings.

“We have also found it very valuable in measuring the properties of fine AM structures like lattices or thin walls.

“The machine is extremely versatile and allows for an array of tests to be undertaken under one roof, so any interested parties can approach us to discuss the possibilities and also to assess what else we can help with through Alloyed’s unique stack of technologies for the manufacture of advanced metal components both by additive or traditional means.”