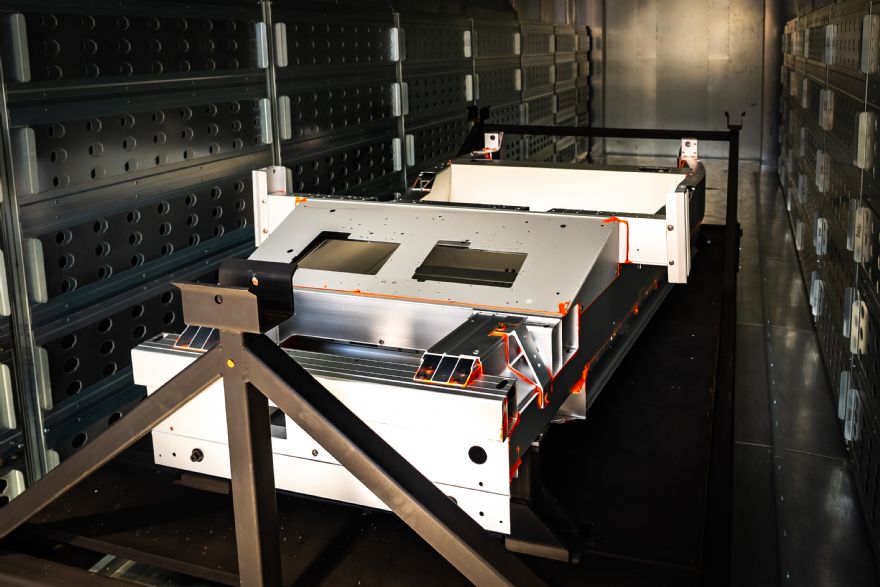

The first extruded and bonded aluminium chassis to be built at Lotus’ new manufacturing facility in Norwich, has been completed. The unit, a chassis for the iconic Lotus Elise, was built for the validation and quality checking of the new manufacturing process.

Although not destined for a final vehicle, it will remain at the factory for testing. As chassis manufacturing volumes grow steadily over the next few months, it will help ensure that the processes adhere to globally recognised quality standards.

The new 12,300m

2 facility has the capacity to build several thousand chassis per year. It will produce around 1,500 units for the Lotus Elise, Exige and Evora during 2021.

Set to employ 125 highly skilled people including technicians and engineers, the site also houses the welding and fabrication of sub-frames, suspension components and other key parts for Lotus cars.

The investment from Norfolk-based Lotus, which has its headquarters and sports car manufacturing 10 miles away in Hethel, further demonstrates its commitment to the region.

Lotus announced in July 2020 that as part of its expansion programme it had outgrown existing facilities in Worcester and Norwich, and so would bring together both production processes into one new combined location – Hurricane Way, in the north of Norwich. Tooling has already been upgraded in readiness for a new range of Lotus sports cars to be launched in the coming years.

David Hewitt, Lotus Cars executive director of operations, said: “The production of this first lightweight chassis is a significant landmark for the new Hurricane Way facility. I would like to thank everyone who has worked extremely hard to ensure that, despite challenging circumstances, it is up and running and on schedule.”

He continued: “In parallel, we are close to finishing our new assembly facility at our Hethel headquarters. By the end of the year, the whole of Lotus’ sports car manufacturing facilities and processes will be either new or vastly improved. This will give us solid foundations to maintain our leadership in the rapidly changing low-volume automotive assembly industry.”