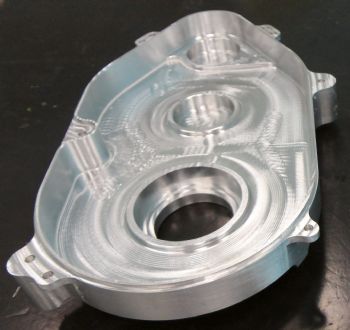

Seacam, Delcam’s Brazilian reseller, worked with Sandvik Brasil to machine aluminium transmission covers for a car being developed by students at the University of São Paulo State (USP).

A reduction of 73% was achieved in the machining time by using the Vortex high-efficiency area-clearance strategy in Delcam’s PowerMill CAM system

for high-speed and five-axis machining (

www.vortex-machining.com).

The students regularly participate in competitions organised by the SAE (Society of Automotive Engineers) for higher-education institutions. The target of each team is to design and build a prototype off-road single-seat car (for enthusiastic amateurs rather than professional drivers).

Founded in 2001, the USP team has improved its results year by year, winning more than 30 awards in various categories — including the national championship in 2009 and 2012. Left- and right-hand versions of the transmission cover were produced on machines at Sandvik Brasil, where using the Vortex strategy saw both parts machined in 3.5hr; similar parts machined using PowerMill without Vortex took 13hr to machine.

Seacam’s Alexandre Magdalon said: “With conventional roughing, it is necessary to limit the depth of cut and step-over of the tool to around 70% of its diameter. With Vortex, it is possible to use a much deeper cut and so remove a larger quantity of material with each pass. There is also a significant reduction in the wear seen on the tool.”