Birmingham-based Delcam plc (

www.delcam.com) has launched the 2014 R2 release of its DentMill software for the milling of dental-implant restorations.

This latest version provides a new mechanism for receiving parts from Delcam’s OrderManager system, more control when using multi-holder fixtures and new options for non-uniform scaling of items.

Smaller enhancements include improved library management and easier set-up for 3+2 machining.

DentMill is an open dental CAM solution, which can mill all types of restoration — including crowns, bridges and implants — from all major dental CAD systems on the market.

It is based on Delcam’s PowerMill software for high-speed and five-axis machining, and it includes advanced strategies to mill restorations in any material from PMMA to titanium.

DentMill is linked to Delcam’s OrderManager work-flow management software, so that the new part library is updated automatically once a new order is received.

OrderManager then manages the whole process from the initial order through to manufacturing and final dispatch. At all stages, users can maintain a ‘real-time’ view of their total order status.

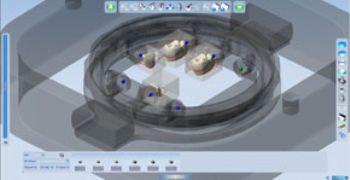

Multi-holder fixtures allow individual restorations to be machined from discrete blocks of material, rather than machining multiple items from a single block. DentMill 2014 R2 gives users more control when using this type of fixture.

For example, if similar types of restoration are being produced in all the positions, the same set of strategies can be applied to the complete group.

Alternatively, individual machining approaches can be used to calculate the tool-paths if each item is of a different type.

In addition, the machining sequence can be set up so that all operations with a particular tool across the various items can be completed in sequence before moving to the next cutter, thereby reducing tooling changes.

DentMill has always offered the option of scaling models to compensate for shrinkage of materials during the sintering process.

This option has been made more powerful with the ability to undertake non-uniform 3-D scaling, allowing more-accurate scaling for better-fitting restorations.