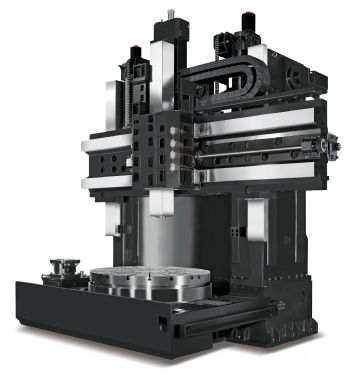

Incorporating a level of functionality normally associated with individual vertical turning centres, vertical and horizontal machining centres and light-grinding machines, the nine machines in the Wele VTC ‘production centre’ series can accommodate table loads up to 50 tonnes; they also feature a Wele-developed hydrostatic table that eliminates bearing backlash and maintains ultra-fine positional increments for indexing within 0.001deg.

Developed by Wele Mechatronic — a strategic-alliance company within the JTETK Group (a sub-group within car maker Toyota and owner of Mitsui Seiki and Toyoda Machine Tool) — the Wele VTC series is available in the UK solely through 2D CNC Machinery Ltd, Hinckley (

www.2DCNC.co.uk).

With nine machines in the series, Wele can provide a ‘production centre’ that is “almost tailored to an application” using standard modular elements. As a result, a range of processes can be incorporated into a cycle that includes both heavy-duty and light-duty high-accuracy turning, horizontal and vertical milling, drilling and precision boring.

Moreover, with the ability to automatically exchange different head configurations, five-face machining sequences can be accommodated. Processes can also include the use of vertical internal and external grinding attachments as part of the machining cycle.

Other features of these machines include the use of twin servo-motor drives to position the fully programmable moving cross-rail (W axis) at 20m/min — and its programmed position can be maintained by a clamping force of 18 tonnes. To further maximise the rigidity of a set-up, the heavy-duty cross-rail can be lowered in preference to fully extending the machine’s ram.

The nine variants of the Wele VTC range start with a turning diameter and turning height of 1,600 ¥ 1,200mm (plus a maximum swing of 2,000mm) for the VTC16-20. These dimensions are increased to 4,000, 3,200 and 4,800mm respectively on the largest VTC4032-48.

On the VTC16-20, the 45kW table drive provides a maximum torque of 20,063Nm and a speed range of 2-260rev/min, while the spindle is rated at 15kW 1,600rev/min (304Nm of torque). The positioning accuracy is 0.015mm, and the repeatability is 0.008mm.

For the VTC4032-48 machine, the 4,000mm-diameter table has a 100kW drive giving a speed range of 1-86rev/min and 139,766Nm of torque. Its 15kW spindle has a top speed of 1,200rev/min. The positioning accuracy for the X and Z axes is 0.025mm, and the repeatability is 0.012mm.

A 16-pocket ISO 50 tool magazine is standard across all machines (24 or 32 positions are options). Control is via a Fanuc OiTD; a higher-specification 31iB or Siemens 828 can also be specified, as can a pallet exchange system and a twin-ram variant.