Eynsham-based Meta Vision Systems Ltd (

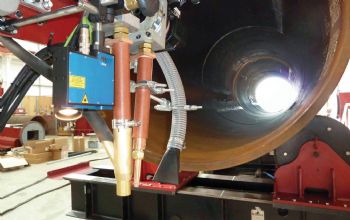

www.meta-mvs.com) has launched a new all-digital version of its patented MetaView system. This combines a laser-camera sensor head with a video monitor that allows a machine operator to remotely control both the horizontal and vertical positions of an SAW (submerged arc welding) head.

The digital version uses a colour touch-screen as the video monitor. Combined with a new high-resolution digital colour camera in the sensor head, this provides much improved image quality and noise immunity; it also offers many new features.

Bob Beattie, Meta’s managing director, said: “As an entry-level product, our MetaView system provides a user-friendly way of getting machine operators away from the welding head. At the same time, it actually improves their control over the position of the head in the joint, leading to better weld quality.

"Just as improved health-and-safety concerns rightly discourage operators from working at heights, so there is an analogous need for a system to allow welding-machine operators to work remotely at a safe distance.”

In addition to providing a ‘less noisy’ image, the digital MetaView’s functionality includes digital zoom, pan and tilt, enabling operators to optimise the image to their preference. Also new is the ability to add a second camera to provide an overview of the weld head, thereby complementing the detailed positional view provided

by the MetaView sensor.