A new generation of touch probes from Heidenhain (GB) Ltd, Burgess Hill (

www.heidenhain.co.uk), is designed for aligning and measuring workpieces, tool setting and detecting cutter wear and breakage on machining centres, milling, drilling and boring machines, as well as on B-axis lathes with automatic tool change.

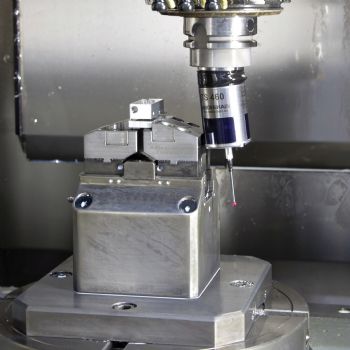

The TS 460 for workpiece touch probing and the table-mounted TT 460 with contact plate for tool length and diameter measurement are compatible not only with Heidenhain controls but also with other leading makes of CNC system.

A particular feature of these units is the ability to feed signals back to the control via an infrared (IR) or radio link, which means that they can be swapped between different machine tools on a shopfloor, irrespective of whether the machines are equipped with IR or radio communication (a video of the TS 460 can be viewed at:

www.youtube.com/watch?v=62iM9PR5TSM).

A further advantage — mainly applicable to larger machines — is mixed operation using both forms of data communication. This allows the long range of radio transmission to reach the tool changer so that a workpiece probe can be activated, ready for use.

Subsequently switching to IR during probing exploits the increased speed and accuracy of data transmission at infra-red frequencies. Another consideration is that a radio beam allows the coordinates of deep features being probed in complex components to reach the receiver, whereas IR may not provide

a signal at all, however close the probe is.

An option is the inclusion of a rubber coupling in the body of the workpiece probes — between the stylus and shank — to protect the unit in the event of an axial collision (an instruction is sent automatically to the control, which immediately stops the axis feed drives). Other features include an ‘intelligent’ battery management system.

Heidenhain also offers two cable-connected models that have even smaller dimensions: the TS 260 workpiece touch probe, which is suited to use on grinding machines as well as machining centres; and the TT 160 touch probe for tool detection and measurement.