Researchers at Dartmouth College (

www.dartmouth.edu) have developed a ‘smart ink’ that turns 3-D printed structures into objects that can change shape and colour.

The innovation promises to add even more functionality to the 3-D printing process and could pave the way for a new

generation of printed materials.

Many 3-D printing protocols rely on photo-curing resins and result in hard plastic objects with rigid but random molecular architectures.

The new process allows designers to retain specific molecular alignments and functions in a material and converts them for use in 3-D printing.

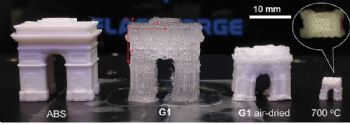

By using a combination of new techniques in the pre-printing and post-printing processes, researchers have been able to reduce printed objects to 1% of their original size and with 10-times the resolution.

The 3-D printed objects can even be animated to repeatedly expand and contract in size through the use of supramolecular pillars. With fluorescent trackers, the objects can be made to change colour in response to an external stimulus such as light.

The ability to reduce the size of an object after printing while preserving functional features and increasing resolution allows inexpensive printers to print high-resolution objects that were once only possible with much more advanced printers.

According to the study, the ‘smart ink’ can print at a rough 300µm resolution, but the end product will feature a much finer line width of 30µm.

Chenfeng Ke, an assistant professor of chemistry at Dartmouth, said: “This process can use a $1,000 printer to print what used to require a $100,000 printer.”

While researchers believe that this technology is still some way from intelligent 3-D systems that can dynamically change their configuration, current uses for it could include precision filters and storage devices.

Over time, researchers expect that the process might result in a new class of macro-scale 3-D printed objects that could be used to deliver medicine or produce high-resolution bone replacements.