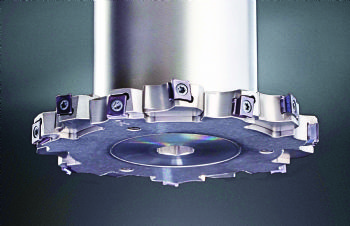

A new side milling cutter that provides stepless adjustment of groove width has been introduced by Paul Horn GmbH; it is available through the firm’s UK subsidiary — Ringwood-based Horn Cutting Tools Ltd (

www.phorn.co.uk).

The milling body features a central sleeve that allows the required groove width to be adjusted easily on a pre-setter.

Horn says that dimensional accuracy, stability and process reliability are assured, as the torque generated during machining is dissipated into the cutter body, of which there are two types.

The first, which has a cutting-edge diameter of 100mm, is equipped with 14 Type 406 indexable inserts, which produce seven effective cuts ranging in width from 9.6mm to a maximum of 12.9mm. The maximum milling depth is 20mm.

The second body type is equipped with 12 cutting inserts of Type 409 and has a cutting-edge diameter of 125mm. On this tool, the cutting width with six effective cuts can be adjusted between 12.9mm and 18.8mm. Here, the maximum milling depth is 32.5 mm.

The 406 and 409 indexable inserts are precision-ground and tangentially screwed to the cutter body; they also feature double positive axial and radial rake angles for a ‘soft ’cut, while a trailing chamfer produces a secondary cutting edge that results in high levels of surface finish at the base of the groove and on the flanks.