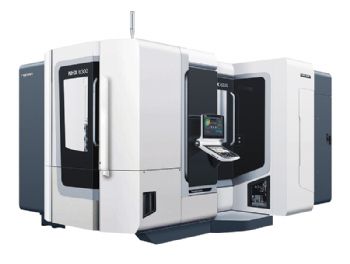

With experience gained from installing over 6,000 NH- and NHX-series horizontal machining centres (HMCs), DMG Mori, which has a UK subsidiary in Coventry (

www.en.dmgmori.com), has introduced another model — the NHX 6300 2nd Generation. This features a new Fanuc control and the manufacturer’s CELOS app-based user interface for the administration, documentation and visualisation of orders, processes and machine data.

Improved machine rigidity ensures highly productive cutting performance, coupled with the precision required in demanding industries such as aerospace. For example, up to 462cm

3of titanium can be converted into chips every minute with an 80mm-diameter porcupine cutter in a PowerMaster-series spindle (with up to 1,413Nm of torque).

Even the standard spindle is rated at 12,000rev/min (807Nm of torque), while a third version with 16,000rev/min is

intended for customers needing higher speeds for even better surface finishes.

The 50 taper (optionally HSK-A100) HMC offers a 1,050 x 900 x 1,030mm work envelope and rapids of 60m/min. The NC rotary table is designed for pallets up to 630 x 630mm and table loads up to 1,500kg.

The maximum workpiece height is 1,300mm. The standard wheel-type magazine has space for 60 tools, with optional magazines accommodating up to 330 tools.

Roller guideways are fitted to the orthogonal axes, as are 0.005μm-resolution linear encoders supplied by group company Magnescale — and precision can be further enhanced if optional coolant-temperature control is specified.

Efficient chip removal and coolant filtration ensure reliable and continuous operation, even when metal removal rates are high — such as when machining cylinder head castings and gearbox housings.

The twin-pallet design enables the NHX 6300 2nd Generation to be connected to a linear pallet pool; and eight machines can be linked into a flexible manufacturing system with up to five set-up stations and space for a maximum of 99 machine pallets. A video of the machine in operation may be viewed at the Web site (

www.dmgmori.co.jp/en/products/machine/id=1529).