Julien SA, a mould maker serving the automotive industry from three sites in France plus one each in Turkey and Slovakia, says WorkNC CAD/CAM software (

www.worknc.com) gives it an advantage that sets it apart from competitors, with superior lead time and quality and expertise; and as a Beta tester for WorkNC, Julien found that a new function introduced in the latest release — 2019 R1 — more than halved the finish-machining times on certain parts.

The company makes moulds for interior linings, boot-compartment trim and roof linings, along with parts for soundproofing and thermal barriers made of aluminium and textiles.

Based at a 10,000m

2 head office in Le Creusot, France, programming manager Sergio Couto is responsible for preparing production and implementing the product manufacturing process; and although Julien makes a small number of moulds for the aerospace industry, most of its customers are major automotive groups requiring short lead times.

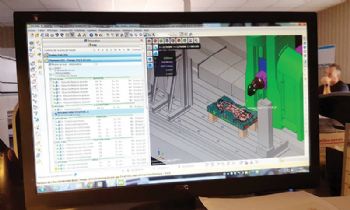

WorkNC, which is installed on seven computers on the company’s network, drives three five-axis machine tools (a Breton, a Durango and a Rambaudi) and four 3+2 machines (a Goglio, an FPT, an Anayak and a Soraluce).

Explaining how WorkNC is an integral part of Julien’s full production operation, Mr Couto says the process begins after the programming team receives an assessment from the engineering office with the purchase order.

“Firstly, we analyse the Catia file of the part to be produced, allowing us to isolate items that need to be precise, and to determine what applications are feasible.

"With the aid of WorkNC’s Catia interface, we can re-establish the Catia construction tree; this is crucial, as this data is of paramount importance to our business, and WorkNC is one of the few applications that allow this.”

Julien then focuses on the number of parts that need to be produced and creates the models in WorkNC, adding offset allowances and any other details required for accurate machining.

“The next step is to prepare the production phase and run tool-path calculations. We establish machining schedules and adapt WorkNC tool-paths to the specific machine to be used.

“Occasionally, we don’t know which machines will be available, so we need to generate generic tool-paths. This highlights the importance of Machining Contexts in WorkNC, because we often have to switch to another machine at the last moment.”

The final phase is in the workshop, where WorkNC’s simulation function validates the process before a machine starts cutting metal. “WorkNC’s powerful programming allows us to undertake ‘lights out’ machining and operate 24/7.”

Finishing strategy

As a Beta tester for WorkNC, Julien trialled a new finishing strategy that allows users to ‘break free’ from previous constraints caused by tool shapes.

Mr Couto says: “WorkNC 2019 R1 adds the Z-level pattern to the Advanced Tool-form technology, allowing for tool shapes like barrels, ovals and parabolics to be calculated over the part surfaces, including negative allowances.

Moreover, the use of the Advanced Toolform strategy with circular-segment cutters, rather than traditional methods, has allowed us to reduce finishing machining times from 32hr to 14hr.”

WorkNC, which is part of the production software business of Hexagon Manufacturing Intelligence, is fully integrated into every machining phase — analysis, comparison, simulation, machining and verification. Summing up the benefits of using WorkNC, Mr Couto says that tool-path calculation times are no longer an issue.

“We manufacture some large parts — up to 2 x 1.5m — and it is very rare that calculation times are longer than 8hr for all roughing, finishing, rest material, corner re-machining and mechanical operations such as drilling and pocket machining. Furthermore, it is easy to learn how to use the software — even for our employees who have never done any

programming before.”

The company has also bought a mobile measuring arm from Hexagon, so that it can make precise measurements at different stages of the manufacturing operation — and make immediate decisions to either modify the pro-cess or continue with it when a doubt arises.

Explaining why Julien first invested in WorkNC in 1994, and how it has developed since then, Mr Couto said: “In the ’90s, mould makers started receiving files from India and China, in which radii and planar surfaces did not conform to the original part, and it was no longer possible to program with Catia.

Even back then, WorkNC could rapidly generate a tool-path, irrespective of a part’s complexity and imperfect surfaces.

“WorkNC has subsequently developed in line with the requirements of milling operators, who had previously programmed tool-paths directly into the machine tools. Today, we have total confidence in working with the software, which also helps us to take issues such as holidays, sickness absences and machine down-time in our stride.”