To help fabricators and manufacturers drive continuous improvement in traceability, documentation, asset management, productivity and quality, Esab Welding & Cutting Products (

www.esab.com) has introduced its new Esab Digital Solutions platform.

This includes Esab WeldCloud and Esab CutCloud, which connect digital ecosystems for manual/robotic/automated welding and cutting automation respectively.

Esab recently demonstrated a new architecture that was powered by Microsoft Azure IoT and used the ThingWorx Industrial Innovation Platform from PTC.

Esab’s Mike Pantaleano said: “Eliminating the need for an on-the-premises server or large IT infrastructure especially helps job shops and smaller operations gain the benefits of data management.

"Our reference architectureusing ThingWorx also allows for on-premises and hybrid configurations, thereby enabling Esab to configure and scale a connected solution for companies of all sizes.

“Furthermore, for companies without IIoT-enabled (Industrial Internet of Things) power sources, the new Esab WeldCloud Universal Connector works with virtually any welding power source.

It can send data to Esab WeldCloud, including arc on time, welding parameters and start/stop information.”

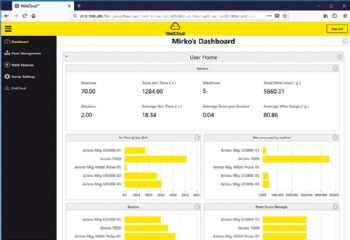

New functionality in Esab WeldCloud enables managers to view high-level dashboards with a simple mouse click.

For example, an operations manager could view the following data for a fleet of welding machines: total arc time, average arc time per weld, number of weld sessions, total weight of wire used, wire used by each station and average machine errors per session.

A supervisor can easily view statistics for any welding operator, identifying desirable performance characteristics and then seek to replicate them.

Other products in Esab’s integrated digital solutions include WeldQAS — a real-time weld quality analytics product.

Ready for connection to Esab WeldCloud, WeldQAS provides the micro details required by engineers and quality assurance personnel; and where many weld-data-capture systems can only log data at 1kHz, WeldQAS captures data at 23kHz (and 234kHz for stud welding).

Faults detected can include poor arc ignition, porosity, burn-through, seam length (too long or short) and seam interruption.