The CNC system manufacturer NUM (

www.num.com), which has R&D facilities in Switzerland, France and Italy (where it also has its major production facility), is helping the Taiwanese machine tool company Chien Wei Precise Technology to develop ‘innovative’ CNC grinding machines for manufacturing specialist gears that are used in robotics applications.

Using NUM’s latest-generation Flexium+ 68 CNC ‘platform’, Chien Wei’s new machines are designed to speed up the production of precision gears with both involute and cycloidal profiles; they are also believed to be the first gear-grinding machines capable of handling both types of gear profile.

There are two machine versions —one for internal gears, the other for external gears.

Founded in 1981, Chien Wei is based in Kaohsiung City, southern Taiwan.

The company initially specialised in precision machine tools such as vertical grinders, jig grinders and machining centres, together with co-ordinate measuring machines (CMMs).

Over time, it also diversified into robotic automation systems, which typically use either planetary gearboxes equipped with involute gears or cycloid drives based on a combination of a ‘reduced epitrochoid rotor’ and a cycloid stator.

Chien Wei says that, while planetary gearboxes have been around for a long time and enjoy extensive use, cycloid drives have far fewer moving parts and offer a more-efficient means of achieving extremely high reduction rates.

A speed reducer with a ratio of 200:1 would typically need a ‘chain’ of three planetary gear boxes with 12 moving involute gears, whereas the same reduction ratio could be achieved with a cycloid drive using one stator and one rotor.

However, the company says cycloid gears are notoriously difficult and costly to produce.

In-house manufacture

In 2015, Chien Wei decided to bring gear manufacturing in-house by developing its own gear-grinding machine, on the basis that by producing its own gearboxes, the company could control quality, shorten lead times and reduce costs — and it would be in a position to sell gearboxes to machine builders, and possibly the machines themselves to gear manufacturers.

Chien Wei initially used a Fanuc 0i-MF CNC system on its gear-grinding machine, in conjunction with Mastercam CAD/CAM software and the use of its own CMM.

However, it soon became apparent that the profile complexity of cycloidal gears meant that data from the CMM was inadequate for controlling the manufacturing process; and customers purchasing these machines would also need to buy an advanced CAD/CAM system — and take on extra staff.

Chien Wei’s president, Mr Lee, said: “We quickly decided that we needed a CNC system that fully supported gear grinding from the outset, so that our customers could simply input the parameters of the gear they wanted, with the CNC then controlling all aspects of the machine’s dressing and grinding processes in real time.

“NUM was an obvious choice, because of its proven expertise in CNC gear-grinding applications.

“The company was also willing to collaborate in the development of the CNC system, which includes an application-specific HMI (human-machine interface) and various dedicated control functions.

“Our new generation of gear grinders, together with NUM’s new profile-grinding technology, now provides the ability to manufacture both cycloid and involute gears on the same machine.”

Adrian Kiener, managing director of NUM Taiwan, says this application highlights the importance of NUM’s decentralised support strategy.

“By providing direct access to the CNC experts and extensive development facilities we have here in Taiwan, as well as those in many other countries around the world, we can give our customers a very fast service that helps them to significantly shorten their time-to-market.

“The package we provided to Chien Wei included the user interface, technology and calculations, as well as all the NC cycles.”

Multi-axis capability

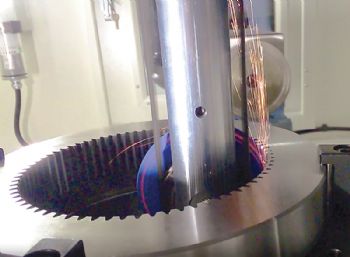

Chien Wei’s internal gear grinder is a nine-axis machine.

The workpiece is fixed to a table mounted on a linear axis that moves it towards the grinding wheel, which is belt-driven (due to space constraints inside the gear) and mounted on a vertical axis driven by a linear motor.

As the grinding wheel spins, it is driven up and down by the linear axis, while the table moves in continuously.

Both flanks of the gear are ground simultaneously. The machine also handles gear dressing.

During the dressing cycle, the entire tool head is moved horizontally to the right, and a symmetrical dressing disk moves along the outer shape of the grinding wheel in three sections — right flank, left flank and tip.

Both cycloids and involute shapes can be dressed.

The external gear grinder is an eight-axis machine that is broadly similar to the internal gear grinder in operational terms. It features a direct-drive grinding wheel and, like the internal gear grinder, it also handles dressing.

In this case, the shape of the tooth gap can be ‘reduced epitrochoids’ or involutes.

Manual correction of the gear-tooth shapes is possible on either machine type (internal and external), and both are controlled by NUM Flexium+ 68 CNC systems equipped with NUM FS153i touch-sensitive operating panels.

The application-specific HMI — jointly developed by NUM Taiwan and Chien Wei — controls both the grinding and dressing cycles; it also allows users to fully specify the required gear profile simply by entering the appropriate parameters.

Graphical DXF files can be imported from — and exported to — CAD systems, and the system features a comprehensive database for grinding wheels and workpieces. Moreover, the NC programs are generated entirely automatically, without any need for operator involvement.