Wolverhampton-based Tungaloy UK Ltd (

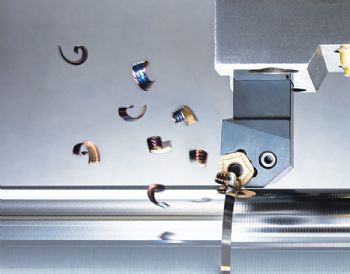

www.tungaloy.com/uk) has introduced its new TurnTen-Feed series of turning inserts.

This has been designed to maximise machining performance and efficiency when undertaking medium to heavy turning operations on large components of the type found in the aerospace, power generation and heavy-industry sectors.

The typically costly components in question call for high machining reliability and tool life predictability; Tungaloy says TurnTen-Feed resolves the performance, material removal rate and tool life challenges faced by manufacturers.

The TurnTen-Feed inserts, which feature 10 cutting edges in double-sided format, are mounted in a secure ‘dovetail clamping’ tool-holder design that ensures “high insert stability during demanding operations”.

Furthermore, the MNW-style chip-breaker is designed to ensure smooth chip flow, while the wiper geometry built into the cutting edge allows high-feed machining at up to 2mm/rev.

Two insert sizes are available. The POMG110612 designation is available with a 15.875mm inscribed circle (IC) diameter, while the POMG130612 has a 19.05mm IC.

TurnTen-Feed inserts are available in a variety of grades, including T9215, T9125 and T9225 from the Tungaloy T9200-series of CVD grades.

Two types of tool-holder are available.

The HD (high depth of cut) holder is suitable for depths up to 7mm, whereas the HF (high feed) holder allows turning at speeds up to 2mm/rev.

The two types of holder can accommodate either type of insert.